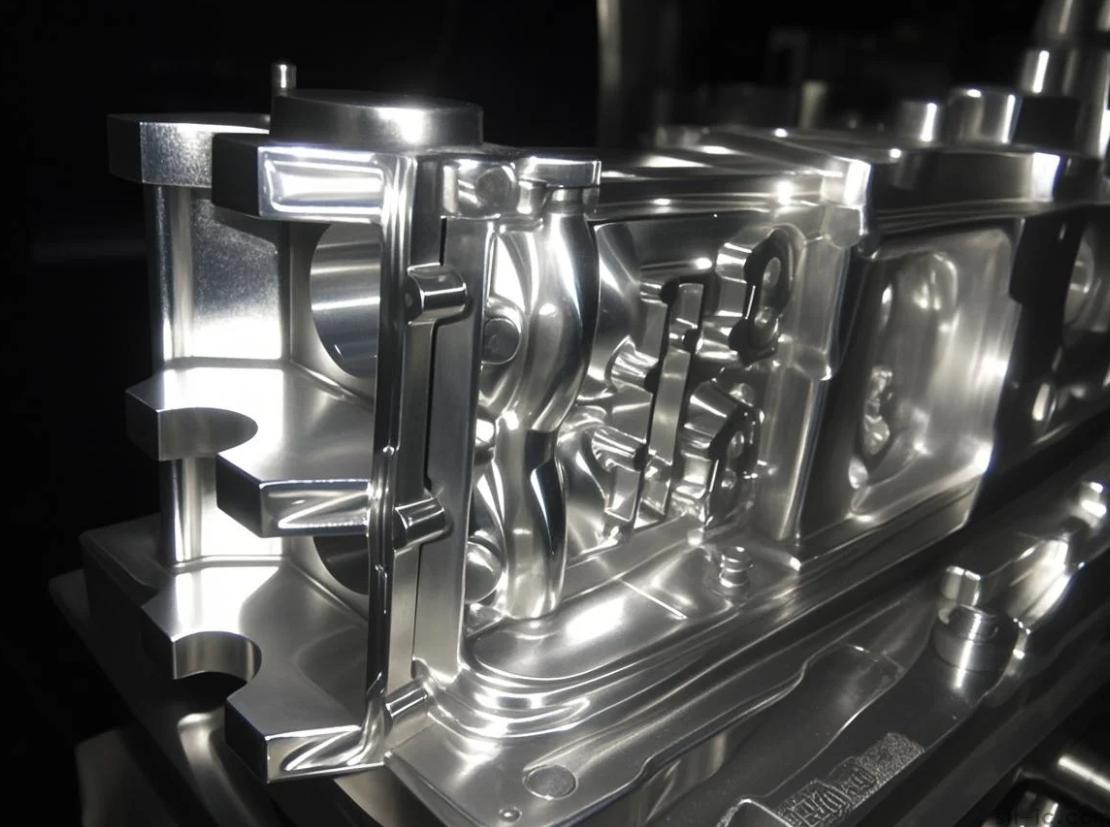

As a leading CNC Machining service provider, EMAR specializes in manufacturing precision large-scale molds for industrial applications. This article explores the technical challenges and our proven solutions for CNC machining large molds.

Challenges in Large Mold CNC Machining

Manufacturing oversized molds presents unique difficulties including thermal deformation, tool deflection, and dimensional stability issues. Our 5-axis CNC machines with thermal compensation systems overcome these challenges through:

- Precision temperature control (±.5°C)

- Rigid machine structures (30% more stable than industry standard)

- Advanced toolpath optimization algorithms

Our Large Mold Machining Capabilities

EMAR's facility features specialized equipment for large mold production:

- Gantry-type CNC machines with 5m x 3m x 2m working envelope

- High-speed spindles (15,000 RPM) for fine surface finishes

- On-machine probing for real-time quality control

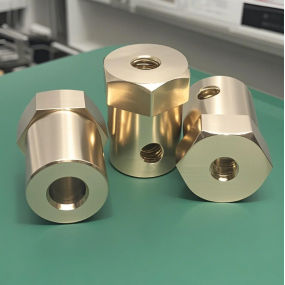

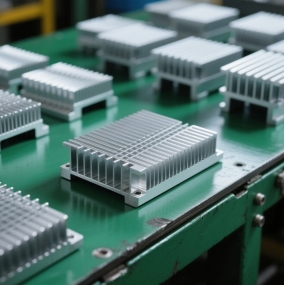

Material Selection Guide

We machine various mold materials including P20, H13 tool steel, and aluminum alloys, each selected based on:

- Production volume requirements

- Part complexity

- Surface finish specifications

Why Choose EMAR for Your Large Mold Projects?

With 15+ years in precision manufacturing, we offer:

- ±.02mm dimensional accuracy

- DFM analysis to optimize mold design

- Complete post-processing services (EDM, polishing, coating)

Visit EMAR's official website to discuss your large mold requirements with our engineering team.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque