Your location:

HOME >

Service >

Numerical control machining > CNC Machining Parts for Batch Production

CNC Machining Parts for Batch Production

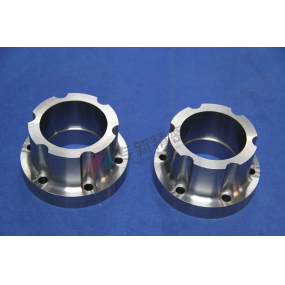

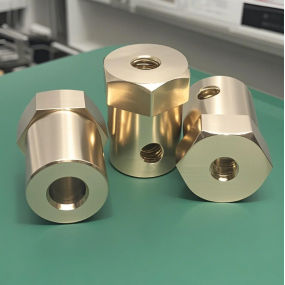

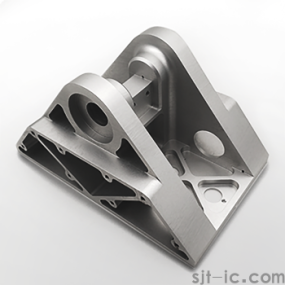

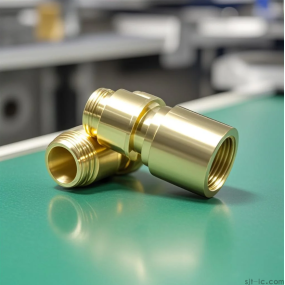

As a leading CNC machining service provider, EMAR specializes in high-precision batch production of machined components for various industries. Our advanced manufacturing capabilit

As a leading CNC Machining service provider, EMAR specializes in high-precision batch production of machined components for various industries. Our advanced manufacturing capabilities ensure consistent quality and cost-efficiency for large-volume orders.

Why Choose CNC for Batch Production?

CNC technology offers unparalleled advantages for mass production of precision parts:

- ±.005mm repeatable accuracy across thousands of parts

- 24/7 automated operation with minimal human intervention

- Scalable production capacity from prototypes to 100,000+ units

- Material versatility including aluminum, steel, titanium, and engineering plastics

Our Batch Processing Capabilities

EMAR's 15,000㎡ facility features:

- 50+ multi-axis CNC machines (3/4/5-axis)

- Automated pallet systems for continuous production

- In-house quality lab with CMM and optical comparators

- Dedicated production cells for specific part families

Industry Applications

We serve:

- Automotive: Engine components, transmission parts

- Medical: Surgical instruments, implantable devices

- Aerospace: Structural components, landing gear parts

- Electronics: Enclosures, heat sinks, connectors

Quality Assurance Process

Our rigorous QC protocol includes:

- First-article inspection (FAI)

- Statistical process control (SPC)

- 100% dimensional verification for critical features

- Material certification and traceability

Cost-Saving Strategies

We help clients optimize batch production costs through:

- Design for Manufacturability (DFM) analysis

- Tooling optimization programs

- Lean manufacturing principles

- Just-in-time delivery options

Contact EMAR today to discuss your CNC machining parts requirements. Visit our website at https://www.sjt-ic.com/ for more technical specifications and case studies.

Contact us to discuss your processing requirements.

Contact Us

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque