Understanding CNC Metal Machining

CNC metal machining is a subtractive manufacturing process that uses computer-controlled machines to shape metal workpieces with exceptional precision. At EMAR, we specialize in transforming raw metal materials into high-quality components through advanced CNC technology. Our process begins with CAD designs that are converted into machine instructions (G-code), guiding our state-of-the-art equipment to remove material with pinpoint accuracy.

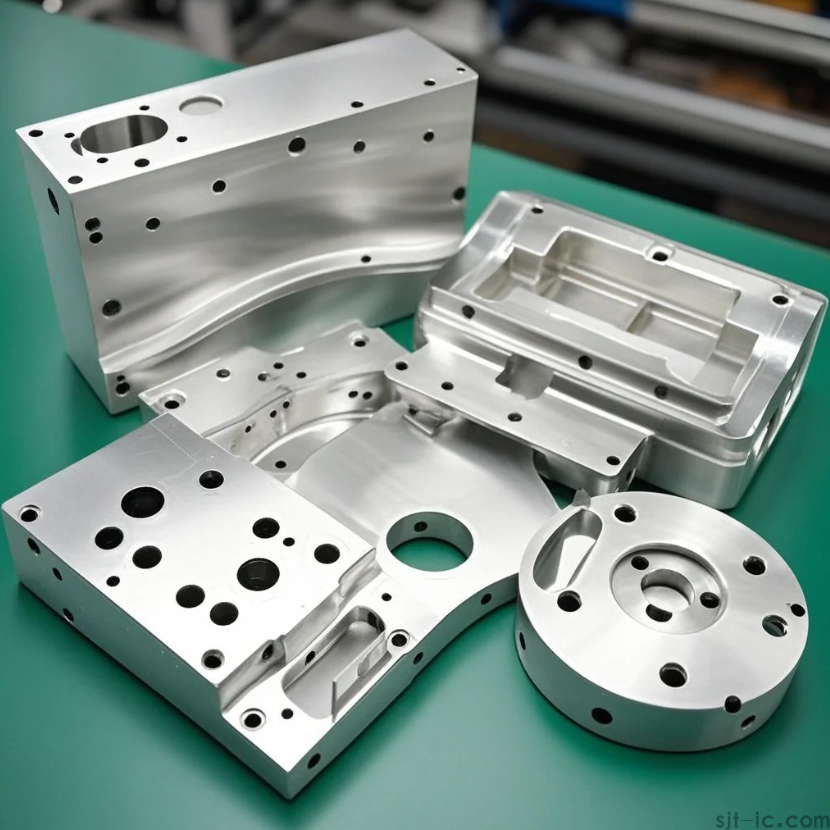

Our CNC Metal Machining Capabilities

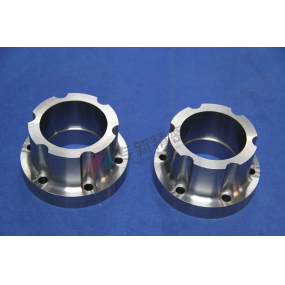

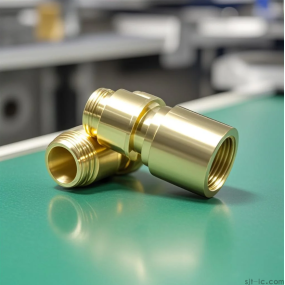

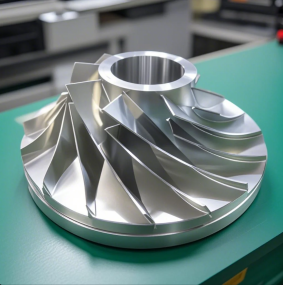

EMAR offers comprehensive CNC metal machining services including milling, turning, drilling, and grinding operations. We work with various metals such as aluminum, steel, brass, copper, and titanium alloys. Our facility houses multi-axis CNC machines capable of producing complex geometries with tight tolerances (up to ±.001 inches). Whether you need prototypes or high-volume production runs, our team ensures consistent quality across all parts.

Why Choose EMAR for Your Metal Machining Needs?

1. Precision Engineering: Our ISO-certified processes guarantee dimensional accuracy and surface finish quality.

2. Advanced Technology: We continuously invest in the latest CNC Machining centers and cutting tools.

3. Material Expertise: Deep knowledge of metal properties ensures optimal machining parameters for each project.

4. Quality Assurance: Comprehensive inspection using CMMs and other metrology equipment verifies every component.

5. Fast Turnaround: Efficient production planning minimizes lead times without compromising quality.

Applications of CNC Metal Machining

Our CNC metal machining services support diverse industries including aerospace (structural components), automotive (engine parts), medical (surgical instruments), and electronics (heat sinks and enclosures). We've successfully delivered solutions for hydraulic systems, robotic assemblies, and custom industrial equipment.

Partner with EMAR Today

For reliable CNC metal machining services that combine technical excellence with competitive pricing, visit our website at https://www.sjt-ic.com/ or contact our engineering team. We'll work closely with you to optimize your designs for manufacturability and provide cost-effective solutions tailored to your specific requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque