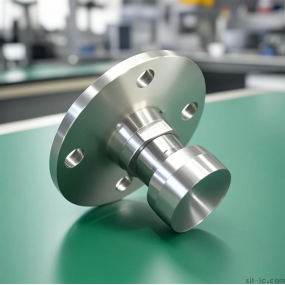

As a leading aluminum CNC Machining factory, EMAR specializes in delivering high-precision components for aerospace, automotive, and industrial applications. Our advanced CNC technology ensures tight tolerances (±.005mm) and superior surface finishes for your aluminum parts.

Why Choose Our Aluminum CNC Machining Services?

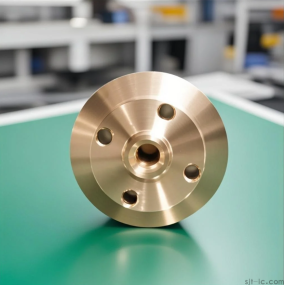

EMAR's CNC machining capabilities include 3/4/5-axis milling, turning, and multi-axis simultaneous processing. We handle all aluminum alloys (6061, 7075, 5052) with proprietary toolpath optimization that reduces cycle time by 15-20% while maintaining ISO 9001-certified quality standards.

End-to-End Aluminum Machining Process

Our production workflow integrates:

Material certification (with Mill Test Reports)

Pre-machining stress relief treatment

High-speed machining (up to 20,000 RPM)

In-process quality inspection (CMM checking)

Post-processing (anodizing, powder coating, etc.)

Applications of CNC Machined Aluminum Parts

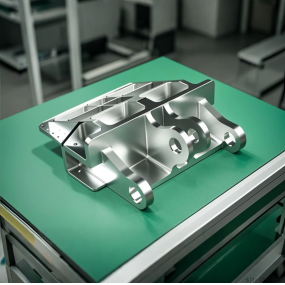

From lightweight structural components to complex heat sinks, our precision machining serves diverse industries with:

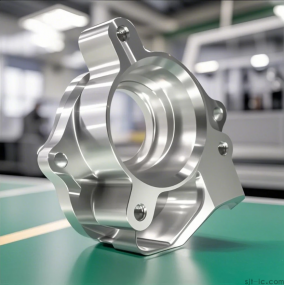

Aerospace: Wing brackets, engine mounts

Automotive: Suspension parts, transmission housings

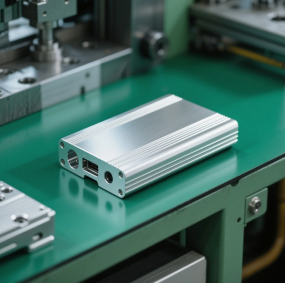

Electronics: Enclosures, heat dissipation systems

Visit EMAR's official website to request a free DFM analysis and instant quotation for your aluminum CNC machining project. Our engineering team provides 24/7 technical support to ensure optimal manufacturability and cost-efficiency.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque