Understanding CNC Precision Machining for Custom Orders

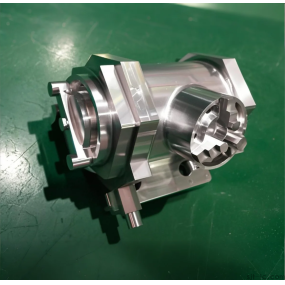

When it comes to CNC precision machining, EMAR stands at the forefront of delivering exceptional custom processing services. Our advanced CNC Machining capabilities allow us to handle complex geometries and tight tolerances with unmatched accuracy.

The EMAR Advantage in Custom CNC Processing

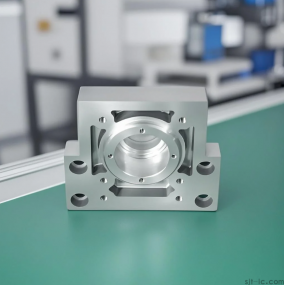

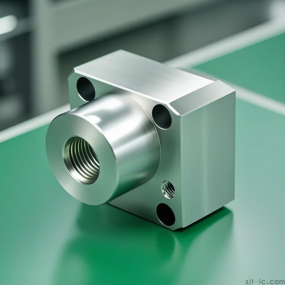

Our CNC precision machining services are designed to meet the most demanding requirements. We utilize state-of-the-art 5-axis CNC machines that can process a wide range of materials including aluminum, stainless steel, titanium, and engineering plastics. What sets us apart is our rigorous quality control system that ensures every part meets or exceeds specifications.

Our Custom Processing Workflow

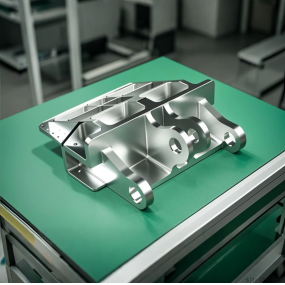

The custom processing workflow at EMAR follows these key steps:

Detailed technical review of customer samples or drawings

Material selection and verification

Precision programming for optimal tool paths

First-article inspection and approval

Full production with in-process quality checks

Final inspection and quality certification

Why Choose EMAR for Your CNC Precision Needs

EMAR's commitment to excellence in CNC precision machining makes us the preferred partner for industries requiring high-quality custom components. Our technical expertise, combined with competitive pricing and fast turnaround times, provides significant value to our clients across aerospace, medical, automotive, and electronics sectors.

Quality Assurance in Every Project

We implement a comprehensive quality management system that includes CMM inspection, surface roughness testing, and material certification. This ensures that every custom processed part leaving our facility meets the highest industry standards and your exact specifications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque