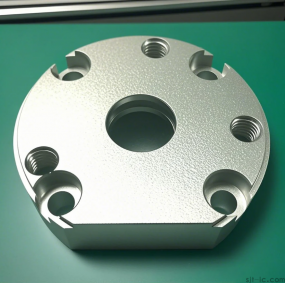

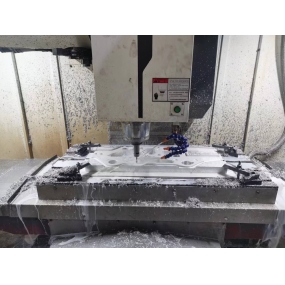

When machining automotive parts, in order to avoid deformation of parts, the following measures can be taken: 1. Rough machining and finishing are carried out separately to reduce the influence of cutting force and cutting heat, so that the deformation caused by rough machining can be corrected during the finishing process. 2. Reduce the influence of clamping force. The following measures can be taken in the machining process to effectively reduce the influence of clamping force on parts:  a. When radial clamping is used, the clamping force should not be concentrated on a certain radial section in the middle, but should be distributed over a larger area, so as to reduce the clamping force per unit area of the workpiece. If possible, install the workpiece in an open ring of appropriate thickness, and clamp it together with this ring. Special jaws that increase the contact area can also be used. If it is a hole positioning point, it is recommended to use both open spindle clamping. B. Change the clamping direction and change the radial clamping to axial clamping. C. The position of the clamping force should be selected in the position where the workpiece rigidity is relatively strong, so as to improve the deformation of the thin-walled parts under the action of the clamping force. d. Make a process boss or process thread to strengthen the rigidity on the workpiece to reduce the deformation caused by clamping. During processing, use a special structure of jaws to clamp, and then dispose of the boss or process thread after processing. 3. Use special fixtures to reduce clamping deformation. 4. Improve the quality of the blank. 5. Increase the stiffness of the parts to prevent excessive deformation. 6. Reduce the cutting force. In actual operation, the staff can flexibly apply the above measures according to the processing requirements and product characteristics to ensure the quality of automotive parts.

a. When radial clamping is used, the clamping force should not be concentrated on a certain radial section in the middle, but should be distributed over a larger area, so as to reduce the clamping force per unit area of the workpiece. If possible, install the workpiece in an open ring of appropriate thickness, and clamp it together with this ring. Special jaws that increase the contact area can also be used. If it is a hole positioning point, it is recommended to use both open spindle clamping. B. Change the clamping direction and change the radial clamping to axial clamping. C. The position of the clamping force should be selected in the position where the workpiece rigidity is relatively strong, so as to improve the deformation of the thin-walled parts under the action of the clamping force. d. Make a process boss or process thread to strengthen the rigidity on the workpiece to reduce the deformation caused by clamping. During processing, use a special structure of jaws to clamp, and then dispose of the boss or process thread after processing. 3. Use special fixtures to reduce clamping deformation. 4. Improve the quality of the blank. 5. Increase the stiffness of the parts to prevent excessive deformation. 6. Reduce the cutting force. In actual operation, the staff can flexibly apply the above measures according to the processing requirements and product characteristics to ensure the quality of automotive parts.

안녕하세요! EMAR의 웹사이트에 오신 것을 환영합니다!

Korean

Korean » »

» »

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque