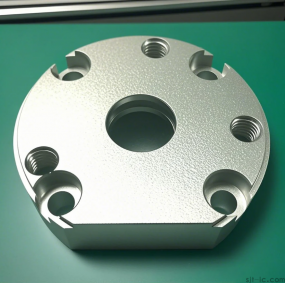

Stamping die is an important process equipment in precision stamping processing and production. It is an effective means to improve product quality, save raw materials, and reflect the technical economy of die products. Durability of stamping die After a period of operation, the punch and concave die lose the working size due to frequent wear and tear, and can no longer meet the technical conditions of the parts. It is determined according to the total number of parts stamped by the die according to the stamping die. A pair of stamping dies is from planning, machining, installation, adjustment to installation and application. There are many processes, long cycles, and high processing costs. Therefore, in addition to high production efficiency and fully meeting the quality requirements and technical conditions of the stamping die, the durability of the die itself is also very important.

Die work parts plus the appearance quality have a very close relationship with the wear resistance, fracture resistance and adhesion resistance of the die, which directly affects the service life of the die. In particular, the surface roughness value has a great impact on the life of the die. If the surface roughness value is too large, stress concentration will occur during operation, and cracks will simply occur between its peaks and valleys, which will affect the durability of the die. It will also affect the corrosion resistance of the surface of precision stamping parts, directly affecting the service life and accuracy of the die. To this end, the following matters should be paid attention to:

1. Timely replacement of worn stamping die guide components and punches;

2. Check whether the gap in the precision stamping die is unreasonable (too small), and increase the gap in the lower die.

3. Minimize wear and tear, improve smooth conditions, smooth plates and punches. The amount of oil and the number of times of oil injection depend on the conditions of the processed materials;

4. Improper grinding methods can cause mold annealing and exacerbate wear and tear. Soft abrasive grinding wheels should be used, with a small amount of knife, sufficient coolant, and frequent cleaning of the grinding wheel.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque