As early as last year, Shenzhen EMAR Precision Technology Co., Ltd. successfully passed the IATF16949 quality management certification, and successfully ranked among the automotive parts processing manufacturers. It is a rare strength manufacturer with automotive parts processing qualifications in Shenzhen. At the beginning of this year, the company successfully passed the high-tech enterprise audit, and the product field was further expanded. In order to better serve users, the company invested heavily in the introduction of high-precision numerical control centering machines. The introduced numerical control centering machine is the Japanese numerical control brand STAR (Star, Star), and has all been debugged and officially put into production.

As we all know, Japan‘s numerical control center machine brands mainly include Nomura, Tsukami, Star, Citizen, etc. The company‘s current assembly models have been basically covered. The new numerical control center machine introduced this time will add points to the company‘s comprehensive processing strength. The model is SB-20R, and the processing progress can be strictly controlled at 0.01mm.

As we all know, Japan‘s numerical control center machine brands mainly include Nomura, Tsukami, Star, Citizen, etc. The company‘s current assembly models have been basically covered. The new numerical control center machine introduced this time will add points to the company‘s comprehensive processing strength. The model is SB-20R, and the processing progress can be strictly controlled at 0.01mm.

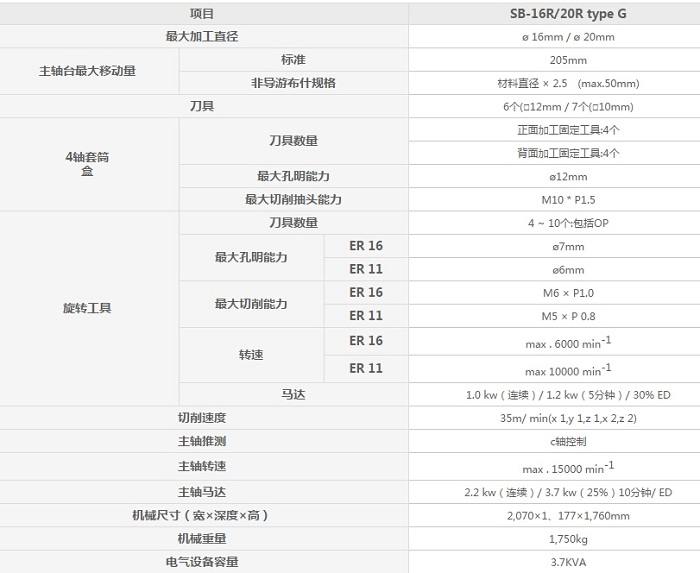

The following are the performance parameters of the newly introduced Star machine:

SB-20RtypeG

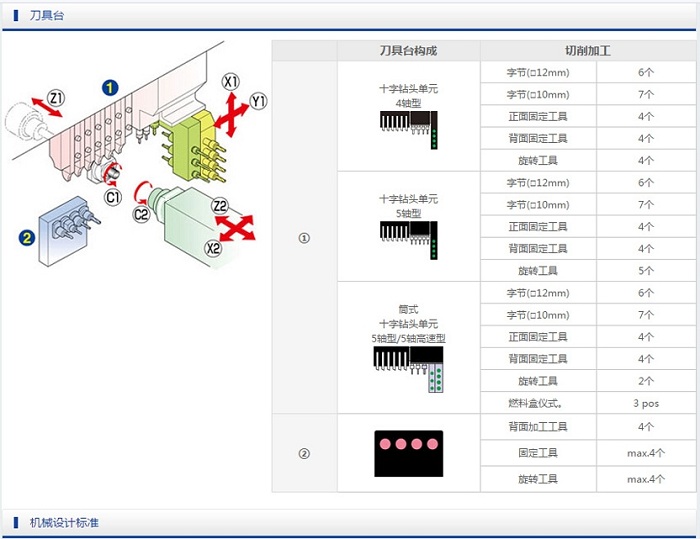

With suitable tool equipment for processing, there are four types of tool holders to choose from.

C-axis control of spindle and sub-spindle changed to standard equipment. (Type E/N/G)

The inclined dovetail groove guide rail structure is adopted to improve the rigidity of the tool holder.

With G.B./N.G.B switching function. (TypeG)

Shenzhen EMAR Precision Technology Co., Ltd. is based on the medical, communication, and optoelectronic industries, gathering market demand. At present, it has successfully developed the precision component processing business in the fields of automobiles, drones, intelligent machines, and office automation. The company currently provides processing services to the outside world, including linkage machining center processing, numerical control lathe processing, heart machining, tool machining, compound processing, etc. Combined with years of processing experience, we constantly optimize the processing technology, pay attention to and close to the user process, and quickly respond to user requests, so that users can focus more on their main business, thereby enhancing customer value.

Shenzhen EMAR Precision Technology Co., Ltd. is based on the medical, communication, and optoelectronic industries, gathering market demand. At present, it has successfully developed the precision component processing business in the fields of automobiles, drones, intelligent machines, and office automation. The company currently provides processing services to the outside world, including linkage machining center processing, numerical control lathe processing, heart machining, tool machining, compound processing, etc. Combined with years of processing experience, we constantly optimize the processing technology, pay attention to and close to the user process, and quickly respond to user requests, so that users can focus more on their main business, thereby enhancing customer value.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque