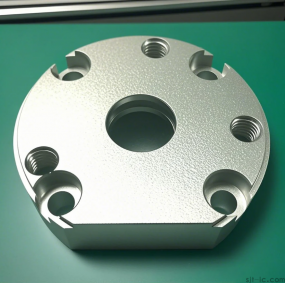

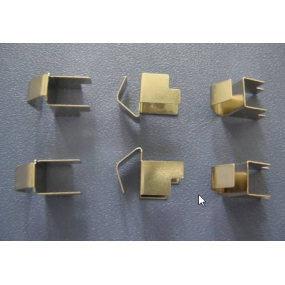

In Metal Stamping processing, it is always inevitable to affect the surface smoothness of the stamped parts and cause a certain roughness, which greatly affects the use of subsequent stamped parts. And for some customers with high requirements, it not only affects the appearance, but also affects the quality and service life of the stamped parts. Therefore, be very careful when processing metal stamped parts.

Then in order to produce high-quality stamped parts, the factory needs to find ways to reduce surface roughness. Next, EMAR will introduce several methods to improve surface roughness for you in detail:

1. Selection of raw materials: In metal stamping processing, many different raw materials are used. Depending on the density of raw materials, the selection of tools and machine tools during processing is directly related to the surface roughness.

2. Cutting consumption: In terms of cutting feed, the amount of surface processing can be appropriately reduced.

3. Select a reasonable processing technology: In the production and processing of stamped parts, the processing process is also very important, and unreasonable processing may affect the processing quality and production efficiency. Many precision stamped parts need to be finished after rough machining to complete the finish requirements;  4. Eliminate the influence of accumulated cutting tumors: Regarding the accumulation of cutting tumors, it is necessary to deal with them faster. Regarding the stamping parts with accumulated cutting tumors on the surface, it is necessary to ensure that there are no accumulated cutting tumors on the surface of the tool.

4. Eliminate the influence of accumulated cutting tumors: Regarding the accumulation of cutting tumors, it is necessary to deal with them faster. Regarding the stamping parts with accumulated cutting tumors on the surface, it is necessary to ensure that there are no accumulated cutting tumors on the surface of the tool.

5. Selection of tool geometric parameters: from the machining tool geometric parameters, it can properly reduce the secondary deflection angle and increase the radius of the tool tip arc, and grind out the polishing edge when necessary, making it easier to cut and reduce the surface roughness.

6. Control the oscillation of the machine tool: by reducing the conflict between the tool and the stamping part, the tool can be sharpened, the cutting fluid can be added, and some stamping parts materials with good durability can be properly heat treated.

The surface roughness of stamped parts has a crucial impact on the use of stamped products, so the factors that affect the surface roughness in the processing of stamped parts should be improved or dealt with in a timely manner to optimize the function of the stamped parts formed by metal stamping.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque