Helloeveryone, manengineeringguywhofocusesoncontentcreationintheindustrialmanufacturingfield.Today, biarkan "stalkaboutwhatmanyuserstrulycareaboutwhensearchingfor" CNCsheetmetalprocessingfactorycostcomposition "howtounderstandquotations, elakkan caj, andevensavenearlyone-thirdofprocurementcosts. Combiningfirst-handinformationfrommyvisitstomultiplefactoriesandin-depthconversationswithtechnicaldirectors, Ihopetohelpyouavoidpitfalls!

1.CostCompositionBreakdown:WhereDoesYourMoneyGo?

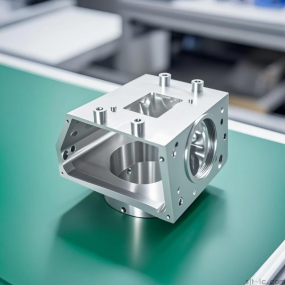

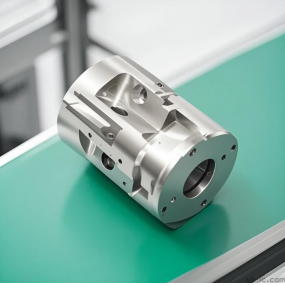

Thecostofsheetmetalprocessingisbynomeansjust "material+workinghours"; itscorecanbedividedintothefollowingcategories:

-Kos Bahan: Thereisasignificantpricedifferencebetweendifferentsheetmaterials. Contohnya, cold-rolledsteelplates, keluli tahan karat, plat aluminium, orgalvanizedplatesmaydifferinpricebythousandsofyuanperton. Selain itu, sheetmaterialutilizationiscrucial whetherthelayoutisscientificdirectlyaffectstheamountofleftovermaterial.

-ProcessingProcedureFees: Inilah "sebahagian besar" kos, usuallychargedbasedonworkinghoursorprocessingdifficulty:

-ProgrammingandSetupFees: Especiallyforsmall-batchorders, theallocationofthisfixedcostismoresignificant.

-CuttingFees: SuchaslasercuttingandCNCpunching, usuallycalculatedbasedoncuttinglengthornumberofholes.

-BendingFees: Relatedtothenumberofbendingtoolsandthecomplexityofangles. Difficult-to-bendshapesmayrequirespecialmoldsormultipleadjustments.

-WeldingandAssemblyFees: Pricedaccordingtoweldlengthandassemblycomplexity.

-SurfaceTreatmentFees: Suchaspainting, penyaduran elektrik, anodizing, dan saringan sutera, chargedbasedonareaandprocessrequirements.

-MoldandSpecialFixtureFees: Ifspecialformingorstampingisinvolved, specialmoldsmayberequired. Theinitialinvestmentisrelativelyhigh, buttheunitcostwilldecreaseduringmassproduction.

-ManagementFeesandProfits: Thenormaloperatingcostsandreasonableprofitmarginsofthefactory.

⚙️2.HowtoEffectivelyControlandReduceProcessingCosts?

Tosavemoney, youneedtostartwithdesignandcommunication:

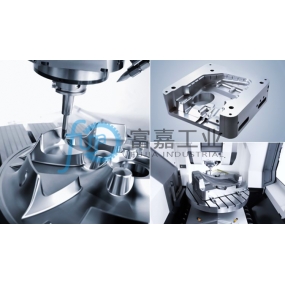

-OptimizingDesignistheSourceofCostReduction: DFM (DesignforManufacturability) iscrucial.Forexample:

-SimplifytheStructure: Onthepremiseofmeetingfunctionalrequirements, reducingthenumberofbendingoperationsandcomplexshapescandirectlyreducebendingprocesstimeandcosts.

-StandardHolesandSizes: TrytousethestandardtoollibraryofCNCpunchpressesorlasercuttingmachines. Non-standardholesandsizesrequirelongerprocessingtimeandhighercosts.

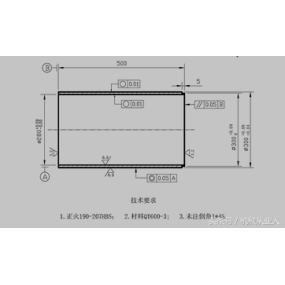

-ConsiderMaterialSpecifications: Choosecommonsheetmaterialspecificationsonthemarkettoreducematerialwasteandprocurementcostscausedbyspecialsizes.

-BenefitsofBatchProductionandPlanning: Placingalarge-batchorderatonetimecansignificantlyspreadtheprogrammingandsetupcostsofasinglepart. Evenifalargequantityisneeded, youcanconsiderphaseddeliverytobalancecashflowandcosts.

-ClearandPreciseCommunication: Providingaccurateandstandardizeddrawingsandtechnicalrequirementscanreducereworkandwastecausedbymisunderstandings. Communicatewiththemanufactureraboutdesignatanearlystage theirprocesssuggestionscanhelpyouavoidpitfallsinadvance.

3. Jawapan Masalah: CoreCostQuestionsUsersCareAboutMost

S: Whycanquotationsfromdifferentmanufacturersvarysomuchforthesamedrawing?

J: Thisisoftenduetodifferencesinequipmentefficiency, pelan proses, materialprocurementchannels dan kos pengurusan. Largefactoriesmayhaveadvancedequipmentandhighefficiency, buttheirmanagementcostsarealsohigh; smallfactoriesmayofferflexibleprices, buttheirprocessorqualitystabilitymaybeinconsistent. Thekeyliesinwhetheryourpriorityisprice, kualiti, atau penghantaran.

S: Howtojudgewhetheraquotationisreasonableandwhetherthereare "perangkap"?

A: Adetailedquotationisthefoundation. Bealertto "harga sekali" orexcessivelyvaguequotations. Anda boleh:

-Requestitemizedquotations: Understandspecificcostsformaterials, setiap proses, pembaikan permukaan, dsb.

-Comparemultipleoptions: Obtain2-3detailedquotationsforcross-comparison.

-Payattentionto "hiddencost": Checkifmodificationfees, rushfee, yuran pengangkutan, andmoldfeesarechargedseparately.

4.PersonalOpinion:PriceisNottheOnlySelectionCriterion

Asanindustryobserver, Ibelievethatpursuingthelowestquotationexcessivelymaybeaccompaniedbyrisks. Ioncesawacompanychoosethelowest-pricedsupplier, resultinginmassunqualifiedpartsandeventualrework doublingthecostintheend. Kualiti yang boleh dipercayai, masa penghantaran yang stabil, andtimelyresponsearealsovaluable. Establishinglong-termcooperationwithhigh-qualitysuppliersisoftenamorestableandeconomicalchoice.

5.FutureCostControlTrend:IntelligenceandCollaboration

WiththeadvancementofindustrialInternetandintelligence, optimizingproductionprocessesthroughdatacollaborationisbecominganewwaytoreducecosts. SomeleadingCNCsheetmetalprocessingfactoriesuseERPandMESsystemstoachievetransparencyintheproductionprocess, helpingcustomersunderstandorderstatusandcostcompositioninrealtime, therebyjointlyfindingoptimizationpoints.

IhopethisanalysishelpsyouviewCNCsheetmetalprocessingcostsmorerationally.Thewaytosavemoneyliesinaccuratedecision-makingandeffectivecommunication.

Ifyouneedit, IcanhelpyousortoutanEnglish-ChineseglossaryofCNCsheetmetalprocessingcost-relatedterms (coveringcoreconceptslikeprocessfees, kos tersembunyi dan DFM) tomakeyourcross-bordercommunicationordocumentreviewsmoother.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque