As a leading CNC Machining specialist, EMAR Company provides high-quality solutions for manufacturing CNC lock nuts. This guide explores the technical process, material selection, and quality control measures to ensure reliable anti-loosening performance.

Understanding CNC Lock Nut Machining

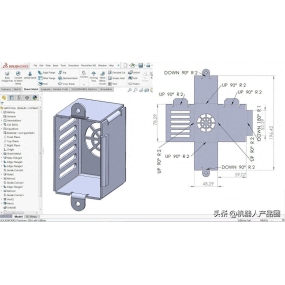

CNC lock nuts require precise threading and deformation control to achieve their anti-vibration properties. Our 5-axis CNC machines maintain tolerances within ±.01mm, crucial for creating the interference fit that prevents loosening under dynamic loads.

Key Manufacturing Steps

1. Material Selection: Typically using grade 8.8/10.9 steel or 304/316 stainless steel

2. Precision Turning: Creating the basic nut profile with controlled wall thickness

3. Thread Cutting: Producing accurate threads with specialized CNC toolpaths

4. Deformation Processing: Forming the locking feature (nylon insert, metal flange, or distorted thread)

5. Surface Treatment: Applying zinc plating or other coatings for corrosion resistance

EMAR's Quality Assurance

We implement vibration testing (per DIN 65151) and torque-angle measurement to verify locking performance. Our CNC machining center in Shanghai maintains ISO 9001 certification, ensuring consistent quality for aerospace, automotive, and industrial applications.

For custom lock nut requirements, contact EMAR's engineering team through our website https://www.sjt-ic.com/ for technical consultation and prototyping services.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque