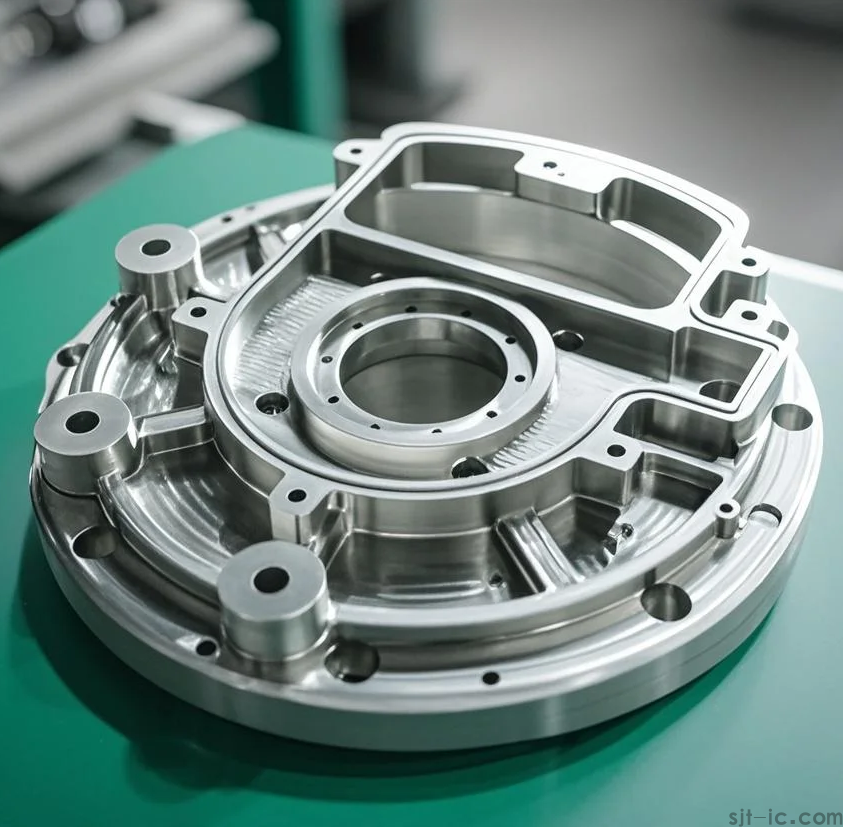

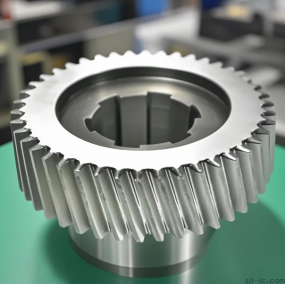

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision engine components for automotive and industrial applications. Our advanced CNC technology ensures exceptional accuracy and repeatability for mission-critical parts.

Why Choose CNC Machining for Engine Components?

Modern engines demand components with tight tolerances (often within ±.005mm) that only CNC machining can consistently achieve. Our 5-axis CNC mills and lathes produce:

- Cylinder heads with complex cooling channels

- Precision pistons and connecting rods

- Turbocharger housings

- Fuel injection system components

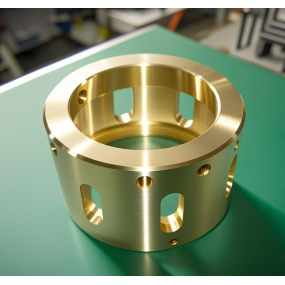

Material Selection for Engine Parts

We machine various high-performance materials including aluminum alloys (6061-T6, 7075), stainless steels (304, 316), titanium, and specialty alloys like Inconel for extreme temperature applications.

EMAR's Quality Assurance Process

Every engine part undergoes rigorous inspection using CMM (Coordinate Measuring Machines) and surface roughness testers to ensure compliance with automotive industry standards (ISO/TS 16949).

Advantages of Partnering with EMAR

- 15+ years of CNC machining expertise

- Quick-turn prototyping and mass production

- DFM (Design for Manufacturing) support

- Competitive pricing with short lead times

Contact EMAR today at www.sjt-ic.com to discuss your engine component requirements and receive a free project evaluation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque