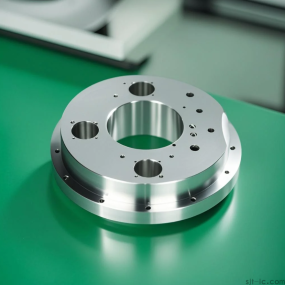

In modern manufacturing, CNC batch processing of small hardware components has become a critical solution for industries requiring high precision and mass production efficiency. As a leading CNC Machining service provider, EMAR Company specializes in delivering exceptional quality for small hardware parts through advanced CNC technology.

Why Choose CNC for Small Hardware Batch Production?

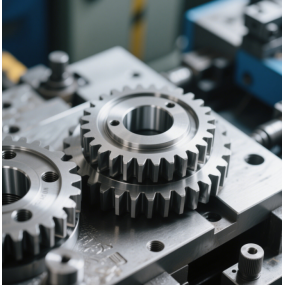

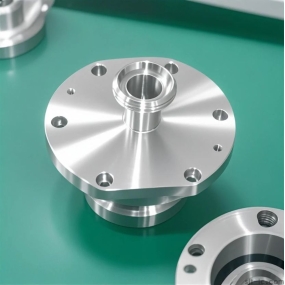

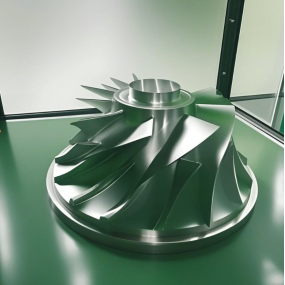

CNC machining offers unparalleled advantages for manufacturing small hardware components in bulk. The automated process ensures consistent quality across thousands of pieces while maintaining tight tolerances (±.01mm). Our CNC batch processing capabilities at EMAR enable cost-effective production of screws, brackets, connectors, and other miniature metal parts with complex geometries.

Our Technical Advantages in Small Hardware CNC Machining

EMAR's manufacturing facility features state-of-the-art multi-axis CNC machines specifically configured for small hardware component production. Key benefits include:

- High-speed machining centers with automatic tool changers

- Precision Swiss-type lathes for micro-components

- In-process quality control systems

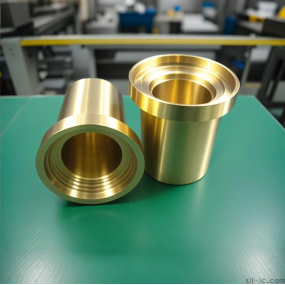

- Material versatility (aluminum, brass, stainless steel, etc.)

- Secondary finishing services (anodizing, plating, polishing)

Streamlined Process for Batch Orders

Our optimized workflow ensures efficient handling of bulk orders:

1. DFM analysis to optimize part design for CNC machining

2. Custom fixture design for small part stabilization

3. Automated toolpath programming for maximum efficiency

4. First-article inspection and sample approval

5. Full production with statistical process control

Industries We Serve

EMAR's CNC batch processing capabilities support diverse industries requiring small hardware components, including electronics, automotive, medical devices, aerospace, and consumer products. Our engineers work closely with clients to meet specific industry standards and regulatory requirements.

For reliable CNC batch processing of small hardware components, trust EMAR Company's expertise. Visit our website at https://www.sjt-ic.com/ to request a quote or discuss your project requirements with our technical team.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque