As a CNC Machining specialist at EMAR (https://www.sjt-ic.com/), we understand that CNC machining transmission worm gears requires precision engineering to meet critical torque transfer and motion control requirements in industrial applications.

Technical Specifications for Worm Gear CNC Machining

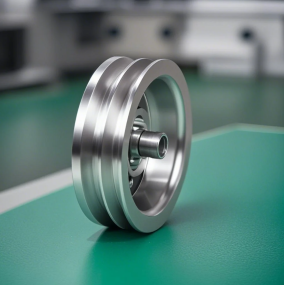

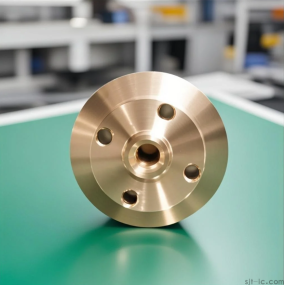

Our CNC machining process for worm gears maintains strict tolerances of ±.01mm, using 5-axis milling centers to achieve the complex helical geometry. Materials range from hardened steel (HRC 45-60) to bronze alloys, with surface finishes down to Ra .8μm for optimal meshing performance.

Quality Assurance Protocol

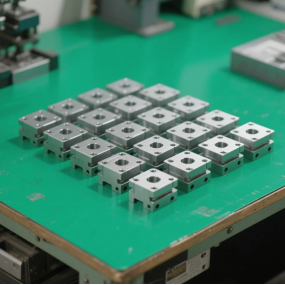

Every transmission worm gear undergoes three-stage inspection: 1) CMM verification of tooth profile accuracy 2) Dynamic balancing test 3) Run-in testing under load conditions matching client specifications.

Why Choose EMAR for Your Worm Gear Production

With 15+ years in precision CNC manufacturing, we offer:

- Dedicated engineering support from prototype to mass production

- ISO 9001-certified quality management

- 30% faster lead times through optimized toolpath programming

- Material traceability with full documentation

Contact our technical team at [company email/phone] to discuss your specific worm gear requirements and receive a DFM analysis within 24 hours.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque