As a leading CNC metal aluminum parts machining specialist, EMAR Company delivers precision-engineered solutions for industries requiring high-quality aluminum components. Our advanced manufacturing capabilities ensure exceptional dimensional accuracy and surface finishes for your most demanding applications.

Understanding CNC Aluminum Machining Processes

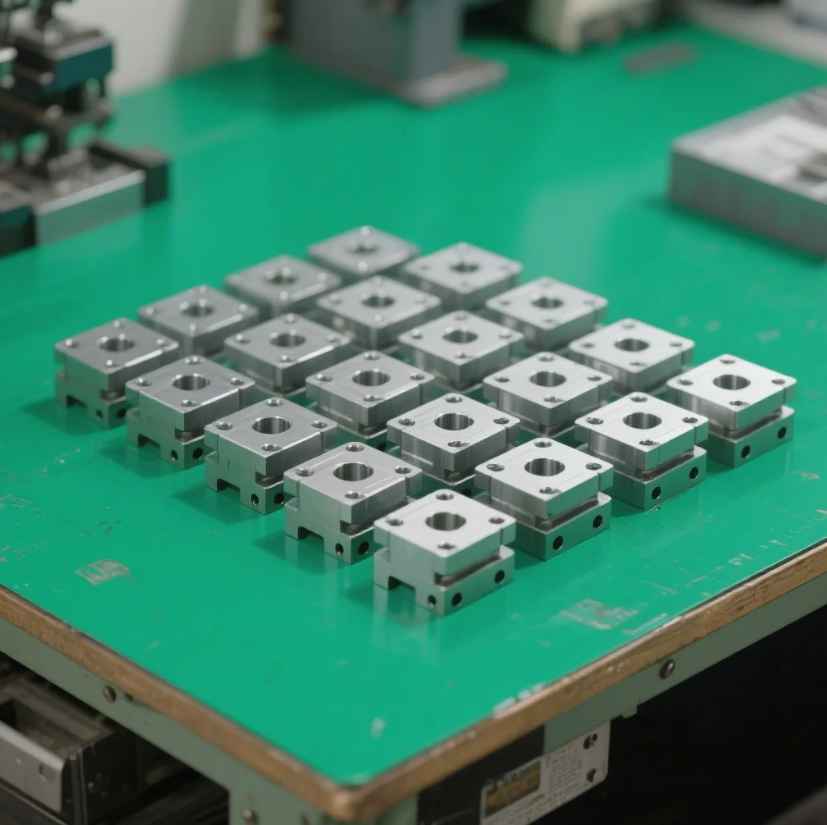

The CNC metal aluminum parts machining process begins with selecting the appropriate aluminum alloy (6061, 7075, or 5052) based on your project requirements. Our 5-axis CNC machines then execute precise cutting, drilling, milling, and turning operations with tolerances as tight as ±.005mm. The lightweight nature of aluminum combined with our machining expertise results in components with excellent strength-to-weight ratios.

Key Advantages of Our CNC Aluminum Machining

EMAR's CNC metal aluminum parts machining services offer several distinct benefits: rapid prototyping capabilities, cost-effective production runs, and the ability to create complex geometries impossible with conventional machining. Our anodizing and surface treatment options further enhance corrosion resistance and aesthetic appeal.

Industry Applications

Our precision aluminum parts serve critical functions across aerospace (structural components), automotive (engine parts), electronics (heat sinks), and medical industries (surgical instruments). Each component undergoes rigorous quality inspection to ensure compliance with industry standards and customer specifications.

Why Choose EMAR for Your Aluminum Machining Needs?

With over 15 years of CNC Machining experience, EMAR combines German-engineered equipment with ISO 9001-certified processes. Our technical team provides DFM (Design for Manufacturing) consultations to optimize your designs for manufacturability and cost-efficiency. From prototype to full-scale production, we guarantee on-time delivery and competitive pricing without compromising quality.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque