In the automotive industry, precision and reliability are non-negotiable. CNC Machining automotive parts has become the gold standard for producing high-performance components that meet stringent quality requirements. At EMAR, we specialize in delivering CNC machining solutions tailored for the automotive sector, combining advanced technology with industry expertise.

Why Choose CNC Machining for Automotive Components?

Modern vehicles demand parts with micron-level accuracy and exceptional durability. CNC machining offers several advantages for automotive applications:

- Tight tolerances (±.005mm) for critical components

- Superior surface finishes for reduced friction

- Material versatility (aluminum, steel, titanium, plastics)

- Repeatable precision for mass production

- Complex geometries in single setups

Our Automotive CNC Machining Capabilities

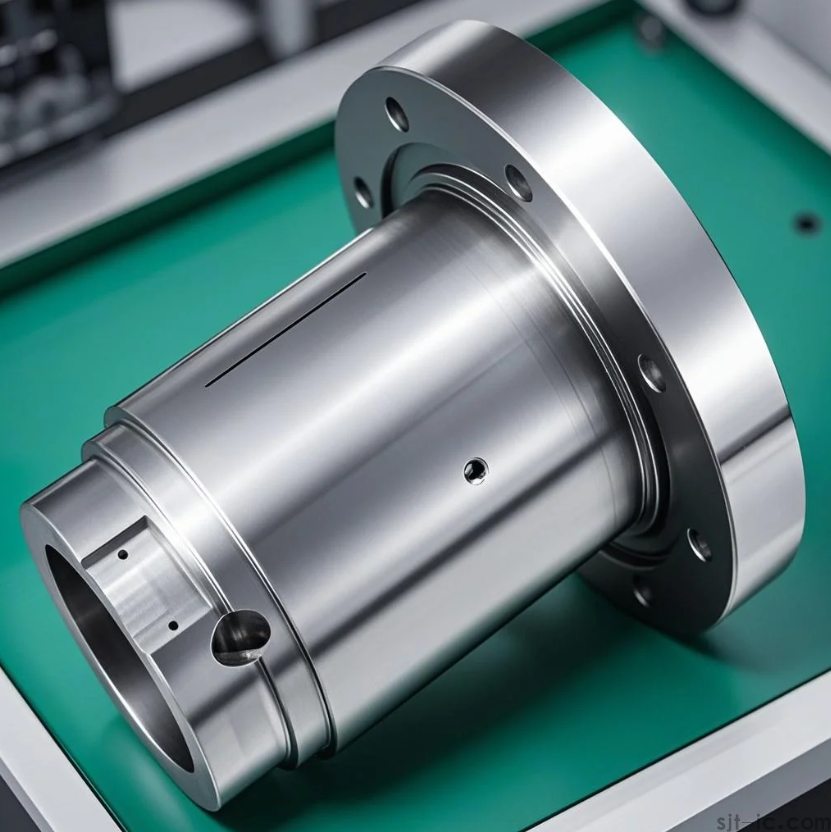

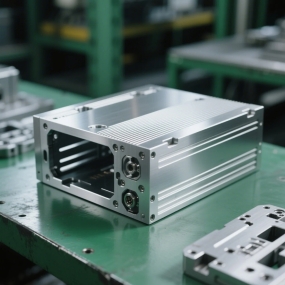

EMAR's 5-axis CNC machining centers produce a wide range of automotive parts:

- Engine components (cylinder heads, pistons, valves)

- Transmission parts (gears, shafts, housings)

- Suspension elements (control arms, knuckles)

- Braking system components

- Custom fasteners and brackets

Quality Assurance for Automotive Standards

We implement rigorous quality control measures including:

- In-process inspection with CMM machines

- Material certification and traceability

- Surface roughness testing

- Dimensional verification per ISO 9001 standards

- PPAP documentation for OEM suppliers

Why Partner with EMAR for Your Automotive Needs?

As a trusted CNC machining automotive parts provider, EMAR offers:

- 15+ years of automotive industry experience

- High-volume production capacity

- DFM (Design for Manufacturing) support

- Just-in-time delivery programs

- Competitive pricing without quality compromise

Contact our engineering team today to discuss your specific automotive component requirements and discover how our CNC machining expertise can enhance your supply chain.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque