Why Choose CNC Machining for Electric Vehicle Components?

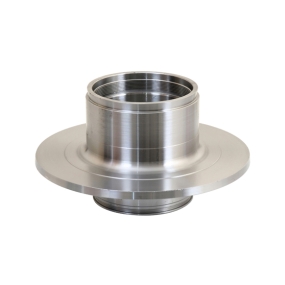

The electric vehicle (EV) industry demands high precision, durability, and lightweight materials—qualities that CNC machining excels in delivering. As a leading CNC machining provider, EMAR specializes in manufacturing critical EV parts such as battery housings, motor mounts, and structural components with unmatched accuracy. Our advanced CNC systems ensure tight tolerances, repeatability, and superior surface finishes, meeting the stringent requirements of modern electric vehicles.

Key Benefits of CNC Machining for EV Parts

1. Precision & Consistency: CNC technology guarantees micron-level accuracy, essential for components like gearboxes and inverter housings.

2. Material Versatility: We machine aluminum, titanium, and high-strength composites—ideal for lightweight EV designs.

3. Scalability: From prototyping to mass production, our CNC machining capabilities support rapid EV industry growth.

4. Reduced Waste: Automated processes minimize material loss, aligning with sustainable manufacturing goals.

EMAR's CNC Machining Solutions for EV Manufacturers

At EMAR, we combine cutting-edge 5-axis CNC machines with ISO 9001-certified processes to produce EV components that outperform industry standards. Our engineers optimize toolpaths and conduct rigorous QA checks to ensure every part—whether a complex cooling plate or a chassis bracket—meets OEM specifications. Partner with us for reliable, high-volume CNC production tailored to the evolving EV sector.

Industries We Serve

Beyond EVs, our CNC expertise extends to aerospace, medical devices, and robotics—all industries where precision machining is non-negotiable. Visit EMAR's official website to explore our full capabilities and request a quote for your next project.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque