In the realm of precision manufacturing, CNC brass machining stands out as a critical process for industries demanding high conductivity, corrosion resistance, and intricate designs. At EMAR, we specialize in delivering top-tier CNC-machined brass components tailored to meet the exacting standards of aerospace, electronics, and automotive sectors. This article explores the technical nuances, applications, and advantages of partnering with a trusted CNC brass machining provider like EMAR.

Why Choose CNC Machining for Brass Components?

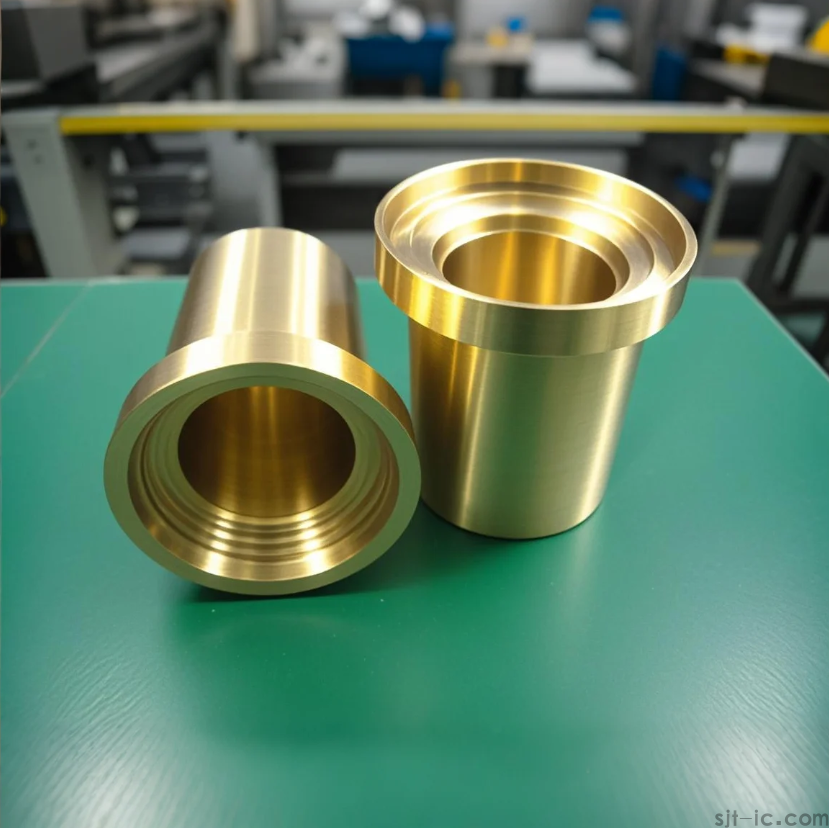

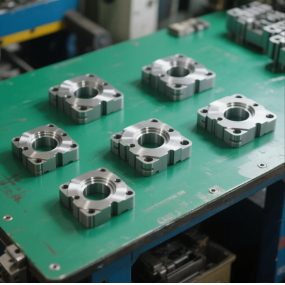

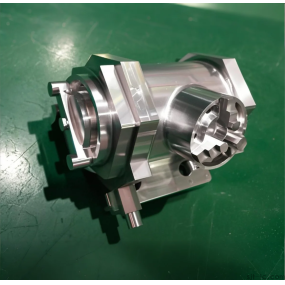

Brass, an alloy of copper and zinc, offers exceptional machinability, making it ideal for CNC brass machining. The process leverages computer-controlled tools to achieve tolerances as tight as ±.005 mm, ensuring dimensional accuracy for complex geometries like threaded fittings, valve parts, and electrical connectors. EMAR's advanced 5-axis CNC machines further enable multi-angle machining in a single setup, reducing lead times by 30% compared to conventional methods.

Key Applications of CNC-Machined Brass Parts

From marine hardware requiring saltwater corrosion resistance to precision gears in medical devices, CNC-machined brass components are ubiquitous. Notable use cases include:

- Electronics: RF shielding enclosures and conductive terminals.

- Plumbing: Dezincification-resistant fittings and valves.

- Automotive: Fuel injection system components with leak-proof threading.

EMAR's Competitive Edge in CNC Brass Machining

Our ISO 9001-certified facility combines cutting-edge technology with rigorous quality control. Every brass workpiece undergoes post-machining deburring and 100% coordinate measuring machine (CMM) inspection. Additionally, EMAR offers:

- Material traceability for alloys like C36000 (free-cutting brass).

- Prototype-to-mass production scalability with 15-day average turnaround.

- Custom surface treatments (e.g., nickel plating, passivation).

For engineers and procurement managers seeking reliable CNC brass machining solutions, EMAR delivers unmatched precision, competitive pricing, and DFM (Design for Manufacturability) support. Visit our website to request an instant quote or technical consultation today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque