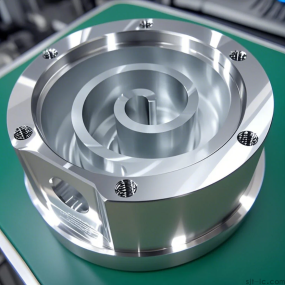

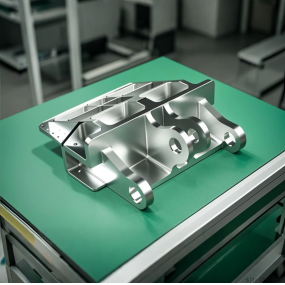

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision small components for various industries. Our advanced capabilities in CNC machining small parts ensure exceptional quality and dimensional accuracy for your most demanding applications.

Why Choose CNC Machining for Small Parts?

CNC technology offers unparalleled advantages for producing small, complex components. Our 5-axis CNC machines can achieve tolerances as tight as ±.005mm, making them ideal for miniature parts requiring extreme precision. The automated process ensures consistent quality across large production runs while maintaining cost efficiency.

Materials We Work With

We machine a wide range of materials for small parts including aluminum alloys, stainless steel, titanium, brass, and engineering plastics. Each material undergoes rigorous testing to ensure it meets the specific requirements of your application, whether for aerospace, medical devices, or electronics.

Our CNC Machining Process for Small Components

1. Design Analysis: Our engineers review your CAD files to optimize manufacturability

2. Machine Setup: Selecting appropriate tooling and fixturing for miniature parts

3. Precision Machining: High-speed machining with continuous quality checks

4. Post-Processing: Deburring, surface treatment, and finishing operations

5. Final Inspection: Comprehensive measurement using CMM and optical comparators

Quality Assurance

EMAR maintains ISO 9001 certification with a complete quality management system. Every small part undergoes dimensional verification and functional testing before shipment. We provide full documentation including material certifications and inspection reports.

Industries We Serve

Our CNC machining services support critical applications in:

- Medical and surgical instruments

- Aerospace components

- Electronics and connectors

- Automotive systems

- Industrial equipment

With EMAR's expertise in CNC machining small parts, you receive precision components that meet your exact specifications, delivered on time with competitive pricing. Contact our engineering team today to discuss your project requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque