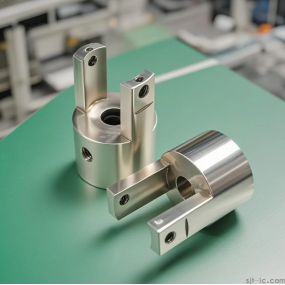

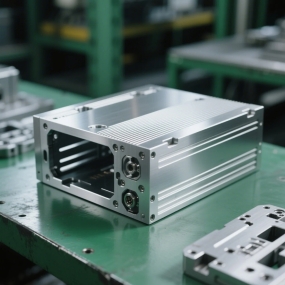

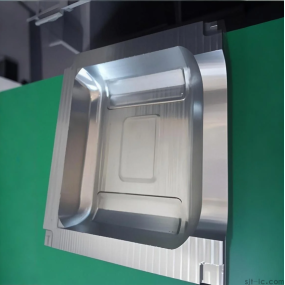

As a leading CNC Machining service provider, EMAR specializes in precision manufacturing of shaft components for various industrial applications. Our advanced CNC technology ensures exceptional accuracy and repeatability for these critical rotational parts.

Understanding Shaft CNC Machining

Shaft components require precise dimensional control and surface finish to ensure proper functionality in mechanical systems. Our CNC machining processes for shafts include turning, milling, grinding, and threading operations, all performed with micron-level precision.

Key Advantages of Our Shaft Machining

1. Material Versatility: We machine various materials including stainless steel, alloy steel, aluminum, and titanium

2. Precision Tolerance: Achieve ±.005mm tolerance for critical dimensions

3. Surface Finish: Deliver Ra .4μm or better surface quality

4. High Volume Capacity: Automated production for large quantity orders

Our CNC Machining Process for Shafts

1. Material Preparation: Precision cutting of raw material

2. CNC Turning: Primary shaping operation

3. CNC Milling: For keyways and special features

4. Grinding: For critical diameter and surface finish

5. Quality Inspection: Full dimensional verification

Why Choose EMAR for Your CNC Machining Needs?

With 15+ years of experience in precision CNC machining, EMAR offers:

- ISO 9001 certified quality system

- Advanced CNC equipment from DMG MORI and Mazak

- Engineering support for design optimization

- Competitive pricing with fast turnaround

Contact our technical team at www.sjt-ic.com to discuss your shaft component requirements and receive a free project evaluation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque