As a leading CNC Machining service provider, EMAR specializes in delivering precision custom molds for various industrial applications. Our advanced CNC technology ensures superior mold quality with tight tolerances and complex geometries.

What Is CNC Machining for Custom Molds?

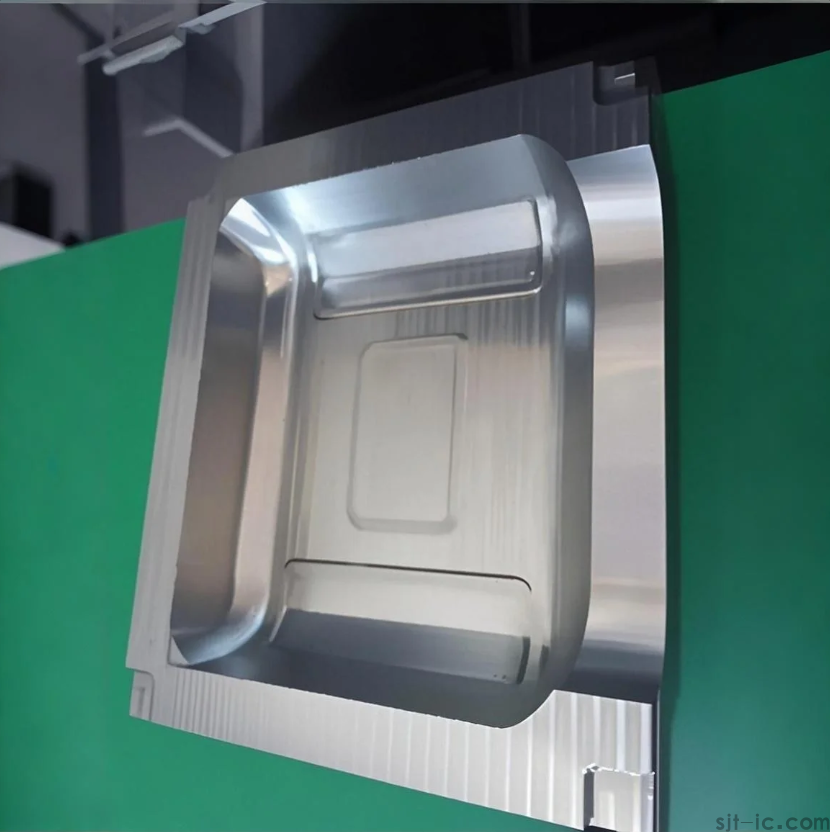

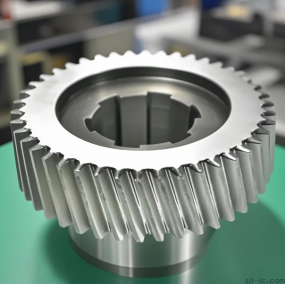

CNC machining custom molds involves using computer-controlled equipment to create precise tooling components from metal or engineering plastics. This process offers unmatched accuracy for injection molds, die-casting molds, and stamping dies.

Our CNC Mold Manufacturing Process

1. Material Selection: We use premium mold steels (P20, H13), aluminum alloys, or copper alloys based on application requirements.

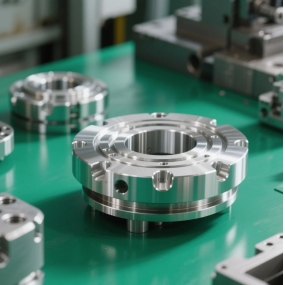

2. Precision Machining: Our 5-axis CNC machines achieve ±.01mm tolerances for critical mold components.

3. Surface Treatment: Optional polishing, texturing, or coating services to enhance mold performance.

4. Quality Inspection: CMM measurement and trial molding ensure every mold meets specifications.

Why Choose EMAR for Your Custom Mold Needs?

- 20+ Years Experience: Proven expertise in automotive, medical, and electronics mold manufacturing

- Advanced Equipment: State-of-the-art CNC machining centers and EDM machines

- Full-Service Solution: From design assistance to post-processing and maintenance

- Fast Turnaround: Prototype molds delivered in as little as 7 working days

Applications of CNC Machined Molds

Our custom molds serve diverse industries including:

• Plastic injection molding for consumer products

• Precision die-casting for automotive parts

• Micro-molding for medical devices

• Composite molding for aerospace components

Contact EMAR today to discuss your custom mold project requirements and benefit from our technical expertise in CNC machining solutions.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque