As a professional CNC Machining service provider, EMAR Company understands that accurate CNC aluminum product processing quotation is crucial for procurement managers and engineers to make informed decisions. This article will explain the key factors affecting pricing and how we ensure cost-effectiveness without compromising quality.

Factors Affecting CNC Aluminum Processing Costs

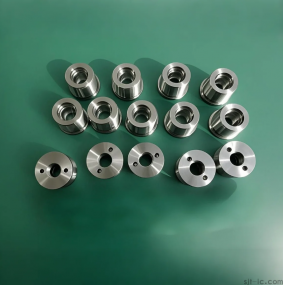

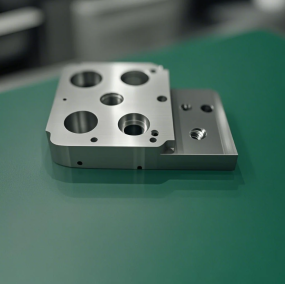

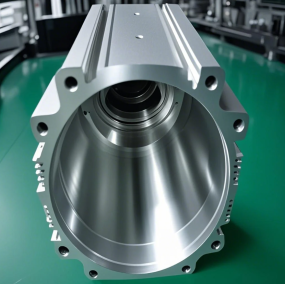

The quotation for CNC aluminum products depends on multiple variables: material grade (6061, 7075, etc.), part complexity, tolerance requirements, surface treatment (anodizing, powder coating), and order quantity. Our engineers evaluate each project individually to provide competitive pricing.

Our Transparent Pricing Strategy

EMAR Company adopts a breakdown quotation system showing material costs, machining hours, tooling expenses, and post-processing charges separately. This transparency helps clients understand where their budget is allocated and identify potential cost-saving opportunities.

How to Get an Accurate Quote Quickly

To receive a precise quotation within 24 hours, please provide: 1) 3D drawings (STEP/IGES format), 2) Material specifications, 3) Quantity requirements, and 4) Surface finish standards. Our automated quoting system combined with expert review ensures both speed and accuracy.

Value-Added Services That Reduce Total Cost

Beyond competitive base pricing, we offer design-for-manufacturability analysis to optimize your parts for cost efficiency, bulk order discounts, and just-in-time delivery options that can significantly reduce your overall production expenses.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque