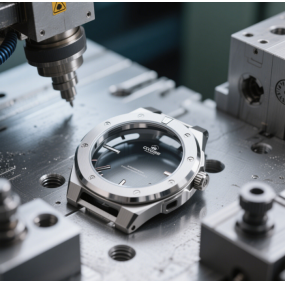

When sourcing CNC Machining parts, procurement managers and engineers often face the dilemma of balancing quality with cost-effectiveness. As an ISO-certified CNC machining service provider, EMAR offers the optimal solution through our advanced manufacturing capabilities and competitive pricing structure.

Key Factors Determining CNC Machining Cost-Effectiveness

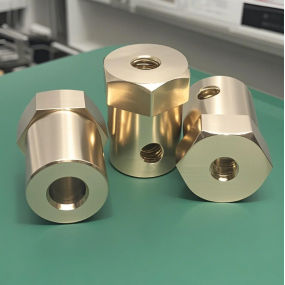

1. Precision Engineering: Our 5-axis CNC machines achieve ±.005mm tolerances, reducing material waste and rework costs.

2. Bulk Production Advantage: Volume discounts for orders exceeding 1,000 units.

3. In-House Tooling: Eliminating third-party tooling expenses saves clients 15-20% on average.

Why EMAR Delivers Superior Value

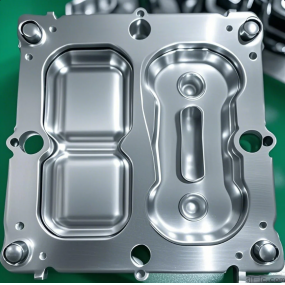

• Material Optimization: Our proprietary nesting software maximizes raw material utilization

• Lean Manufacturing: Automated production lines operate at 92% efficiency

• Quality Assurance: Every part undergoes 3D scanning and CMM inspection

Comparative Advantage in Key Industries

For automotive components, our CNC machining solutions achieve 30% faster cycle times than industry benchmarks while maintaining IATF 16949 compliance. In aerospace applications, our titanium machining capabilities offer the best strength-to-weight ratio at competitive market prices.

Contact our engineering team at www.sjt-ic.com for a free DFM analysis and cost breakdown tailored to your specific project requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque