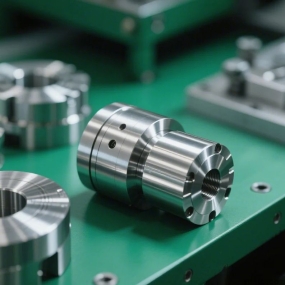

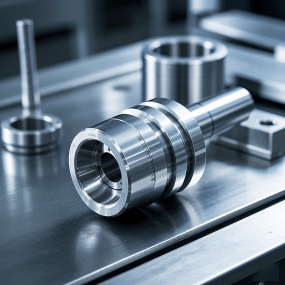

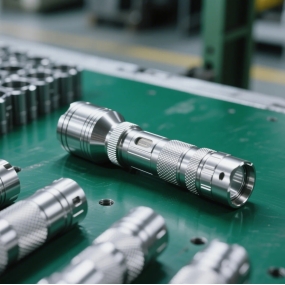

In modern manufacturing, CNC large part machining plays a critical role in producing high-precision industrial components for aerospace, automotive, and heavy machinery sectors. As a leading CNC Machining service provider, EMAR specializes in handling oversized workpieces with micron-level accuracy through advanced 5-axis milling and turning capabilities.

Challenges in Large-Scale CNC Machining

Manufacturers face unique obstacles when machining large components: material stress deformation, thermal expansion during prolonged operations, and maintaining dimensional stability across massive workpieces. Our CNC machining solutions address these through rigid machine structures (up to 10m travel), real-time temperature compensation systems, and proprietary fixture designs that minimize vibration.

EMAR's Technical Advantages

1. Mega-Sized Equipment: 8-ton capacity gantry mills and 15m bed lathes

2. Material Expertise: Machining cast iron (GGG70), titanium alloys (Grade 5), and superalloys (Inconel 718)

3. Quality Assurance: On-machine CMM inspection with .01mm repeatability

Industry Applications

Our large-part machining services support:

- Wind turbine gearbox housings

- Marine propulsion shafts

- Mining equipment structural frames

- Railway bogie components

With ISO 9001-certified processes and DFM analysis included in every project, EMAR delivers large-scale CNC machined parts that meet the most stringent industrial requirements. Contact our engineering team at www.sjt-ic.com for technical consultation and quote within 24 hours.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque