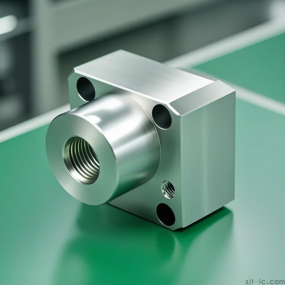

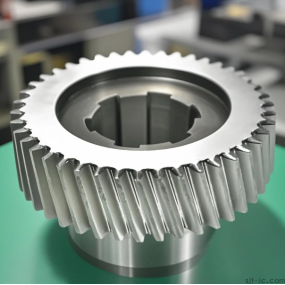

As a leading CNC tungsten steel parts processing manufacturer, EMAR specializes in delivering high-precision machined components for industries requiring exceptional hardness and wear resistance. Our expertise in tungsten steel (carbide) machining ensures superior performance in demanding applications such as molds, cutting tools, and aerospace components.

Why Choose Tungsten Steel for CNC Machining?

Tungsten steel, known for its extreme hardness (up to 92 HRA) and thermal stability, is ideal for components subjected to high stress and abrasive environments. Our advanced CNC machining capabilities overcome the material's brittleness through:

-

Specialized tool geometries with diamond-coated cutters

-

Optimized cutting parameters (low RPM, high feed rates)

-

Rigid machine setups with vibration damping

-

Cryogenic machining techniques when required

Our CNC Tungsten Steel Processing Capabilities

EMAR's facility features 5-axis CNC mills and Swiss-type lathes specifically configured for carbide machining:

|

Process

|

Tolerance

|

Surface Finish

|

|

Milling

|

±.005mm

|

Ra .2μm

|

|

Turning

|

±.003mm

|

Ra .1μm

|

|

Grinding

|

±.001mm

|

Ra .05μm

|

Quality Assurance System

Every tungsten steel component undergoes rigorous inspection with:

-

Zeiss CMM (Coordinate Measuring Machine)

-

Surface roughness testers

-

X-ray density verification

-

Microhardness testing (Vickers scale)

As your trusted CNC tungsten steel parts processing manufacturer, EMAR combines material science expertise with precision machining to deliver components that outperform standard steel alternatives. Contact our engineering team at www.sjt-ic.com for project-specific solutions.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque