Your location:

HOME >

Service >

Numerical control machining > CNC Machining Large Gears: Precision Manufacturing Solutions

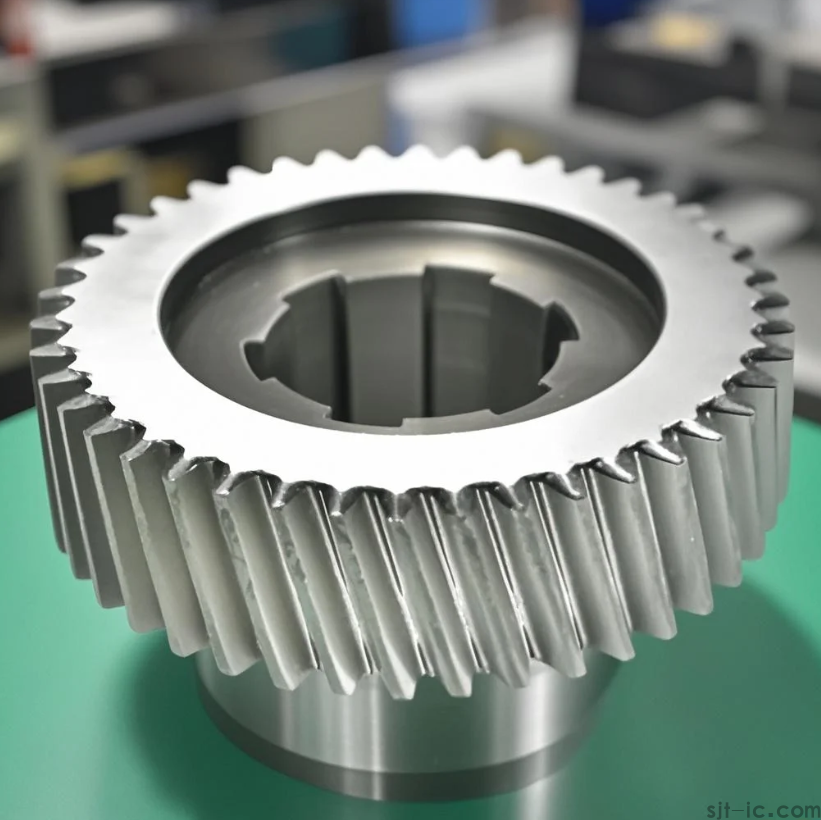

CNC Machining Large Gears: Precision Manufacturing Solutions

As a leading CNC machining service provider, EMAR specializes in manufacturing high-precision large gears for industrial applications. Our advanced CNC technology ensures dimension

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision large gears for industrial applications. Our advanced CNC technology ensures dimensional accuracy and superior surface finish for gears up to 2 meters in diameter.

Why Choose CNC Machining for Large Gears?

Traditional gear manufacturing methods often struggle with large-scale components, but CNC machining overcomes these limitations through:

- ±.01mm dimensional tolerance

- Custom tooth profiles (spur, helical, bevel, worm)

- Material versatility (steel, aluminum, brass, plastics)

- Repeatable precision for batch production

Our Large Gear Manufacturing Process

EMAR's CNC machining workflow for large gears includes:

- 3D modeling and gear design verification

- Material selection and pre-machining treatment

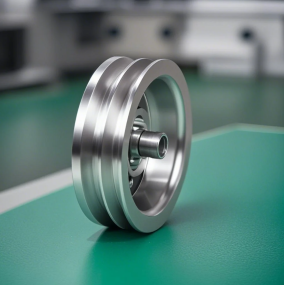

- Precision CNC milling/turning operations

- Heat treatment (when required)

- Quality inspection (CMM, gear testing equipment)

- Surface finishing (grinding, polishing, coating)

Applications of CNC Machined Large Gears

Our CNC-produced gears serve critical functions in:

- Wind turbine power transmission systems

- Mining and construction equipment

- Marine propulsion systems

- Industrial automation machinery

With EMAR's ISO 9001-certified manufacturing facility in China, we deliver CNC machining solutions that meet international quality standards. Contact our engineering team at https://www.sjt-ic.com/ for custom large gear requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque