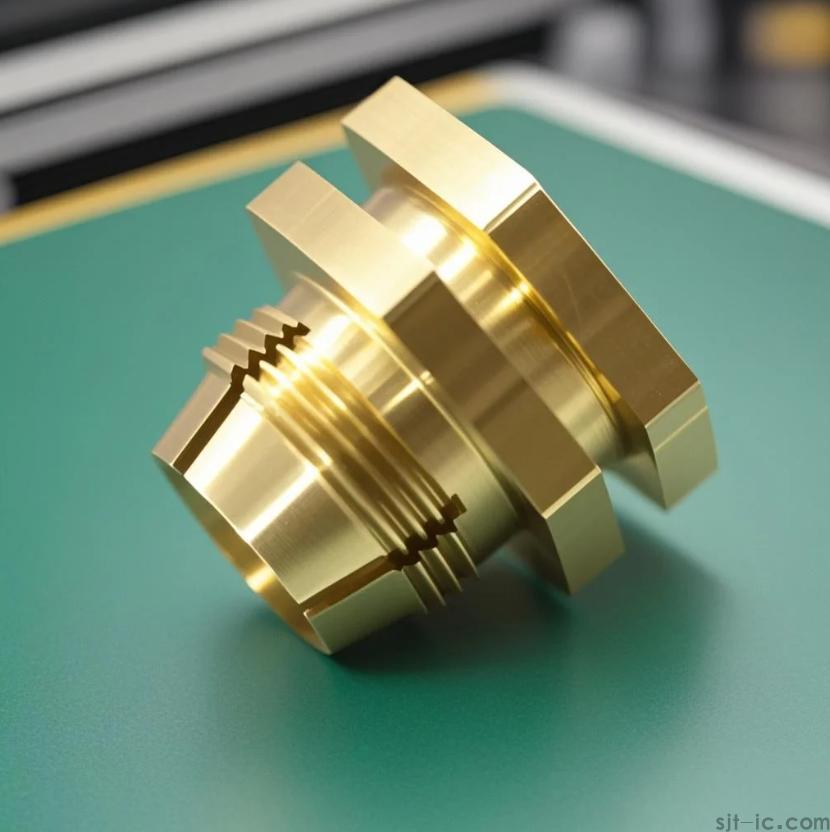

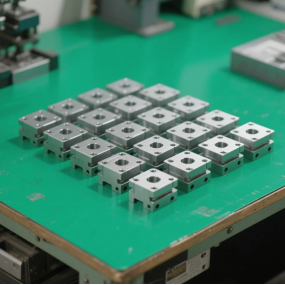

In the realm of CNC copper parts machining, EMAR stands as a trusted partner for industries demanding high conductivity, corrosion resistance, and intricate geometries. Our advanced CNC capabilities transform raw copper materials into precision components that power electronics, aerospace, and energy sectors.

Why Choose CNC Machining for Copper Components?

Copper's unique properties - excellent thermal/electrical conductivity and malleability - require specialized CNC machining expertise. Our ISO-certified facility employs:

- High-speed 5-axis CNC machines for complex 3D contours

- Temperature-controlled environments to prevent thermal deformation

- Micro-machining capabilities (±.005mm tolerance)

- Anti-galling tool coatings to prevent material adhesion

EMAR's CNC Copper Machining Process

Our proven workflow ensures consistent quality:

- Material Selection: C10100 (OFC), C11000 (ETP), or beryllium copper alloys

- Pre-Machining: Stress-relieving heat treatment

- Precision Machining: Adaptive toolpaths for chip control

- Surface Enhancement: Electropolishing or passivation

Applications of Machined Copper Parts

Our CNC copper components serve critical functions in:

- Busbars and electrical contacts (low resistivity)

- Heat exchanger fins (thermal management)

- RF waveguide components (signal integrity)

- Semiconductor tooling (non-sparking)

With EMAR's 15+ years of CNC expertise, we deliver copper parts that meet MIL-STD, ASTM B152, and RoHS compliance standards. Request a free DFM analysis through our website www.sjt-ic.com to optimize your copper part designs for manufacturability and cost-efficiency.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque