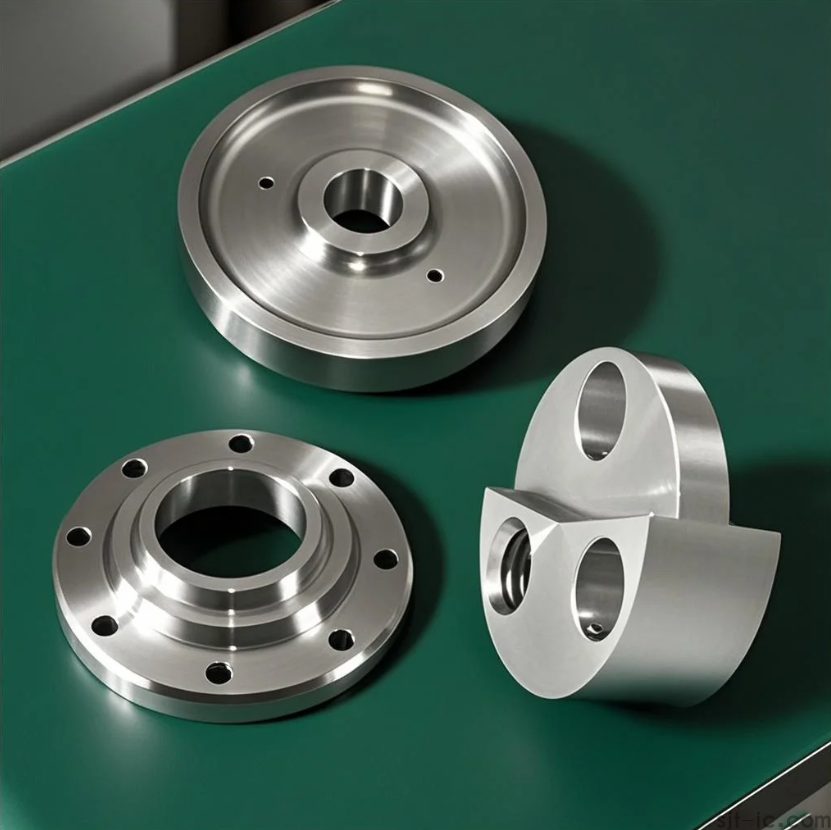

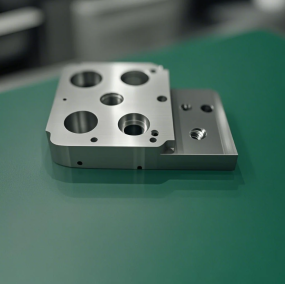

When sourcing a reliable stainless steel CNC precision machining manufacturer, engineers and procurement managers prioritize technical expertise, material compliance, and production scalability. This guide explores key selection criteria while highlighting EMAR's capabilities in delivering high-tolerance stainless steel components.

Why Choose Specialized Stainless Steel CNC Machining?

Stainless steel (grades 303, 304, 316L) demands CNC machining expertise due to its work-hardening properties. EMAR utilizes:

5-axis milling centers with high-pressure coolant systems

Cryogenic machining techniques for austenitic grades

In-process gauging for ±.005mm tolerances

EMAR's Manufacturing Advantages

Our precision machining facility features:

ISO 9001:2015 certified processes

Material traceability from mill certificates

Dedicated stainless steel workshop (cleanroom environment)

Surface roughness control down to Ra .4μm

Industry-Specific Solutions

We serve:

Medical: Implant-grade 316LVM components

Aerospace: AMS 5643 compliant parts

Food processing: Mirror-finished sanitary fittings

With 15+ years in precision machining, EMAR combines advanced CNC technology with metallurgical expertise to deliver corrosion-resistant components meeting ASME, DIN, and JIS standards. Request your project consultation today at www.sjt-ic.com.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque