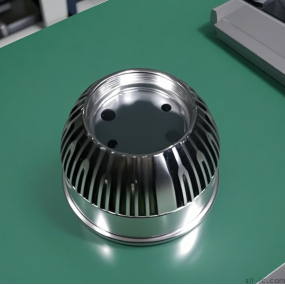

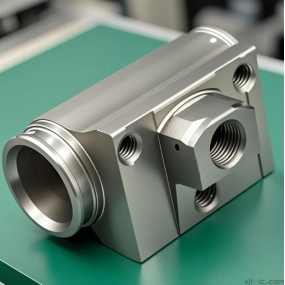

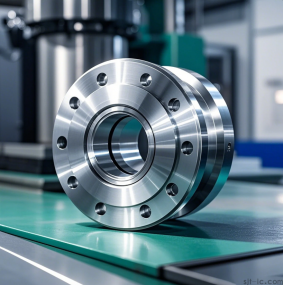

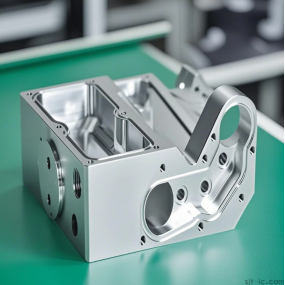

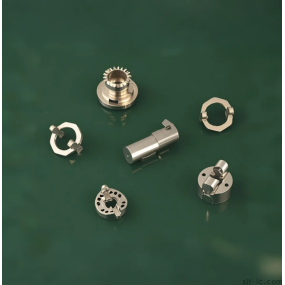

As a leading CNC Machining service provider, EMAR specializes in manufacturing precision copper heat insulation plates for various industrial applications. Our advanced CNC technology ensures exceptional thermal management solutions with micron-level accuracy.

Why Choose CNC Machined Copper Heat Insulation Plates?

Copper's excellent thermal conductivity makes it ideal for heat insulation applications. Our CNC machining process enhances copper's natural properties by creating precise geometries that optimize thermal performance. Compared to traditional manufacturing methods, CNC offers:

±.01mm dimensional accuracy

Superior surface finish (Ra .8μm achievable)

Complex contour machining capabilities

Consistent quality across mass production

Our CNC Machining Process for Copper Components

EMAR follows a rigorous 6-step quality-controlled process for CNC machining copper heat insulation plates:

Material selection: High-purity C11000 copper

CAD/CAM programming with thermal simulation

Precision CNC milling/turning

Surface treatment (optional nickel plating)

3D measurement inspection

Anti-oxidation packaging

Technical Specifications

Our CNC machined copper plates meet the most demanding requirements:

| Parameter | Specification |

|---|

| Thickness Tolerance | ±.05mm |

| Flatness | .1mm/m² |

| Thermal Conductivity | ≥385 W/m·K |

| Maximum Dimension | 800×600×50mm |

Industry Applications

Our precision copper components serve critical functions in:

Power electronics cooling systems

Laser equipment heat dissipation

Automotive battery thermal management

Aerospace thermal protection

With 15+ years of CNC machining experience, EMAR guarantees OEM-quality copper heat insulation solutions. Contact our engineering team at www.sjt-ic.com for custom project consultation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque