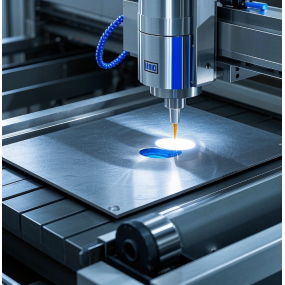

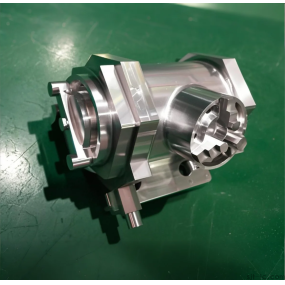

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision semiconductor components for industries demanding micron-level accuracy. This article explores the critical role of CNC technology in producing these specialized parts.

Why CNC Machining for Semiconductor Components?

The semiconductor industry requires components with exceptional dimensional stability, complex geometries, and superior surface finishes. CNC machining offers unmatched precision for creating:

Wafer handling components

Vacuum chamber parts

Precision alignment fixtures

Plasma-resistant components

EMAR's Advanced Manufacturing Capabilities

Our facility features:

5-axis CNC machines with ±.005mm tolerance

Cleanroom machining environments

Material expertise including aluminum alloys, stainless steel, and engineering plastics

Surface treatment options for corrosion resistance

Quality Assurance Process

Every semiconductor component undergoes rigorous inspection:

CMM measurement for dimensional verification

Surface roughness testing

Material certification

Functional testing when required

Industry Applications

Our components serve critical functions in:

Semiconductor fabrication equipment

Wafer inspection systems

Cleanroom automation

Research and development facilities

With EMAR's expertise in CNC machining semiconductor components, we deliver solutions that meet the exacting standards of the electronics manufacturing industry. Contact our engineering team to discuss your specific requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque