CNC Mold Processing Manufacturer

As a leading CNC mold processing manufacturer, EMAR Company specializes in delivering high-precision mold solutions for various industries. Our advanced CNC Machining capabilities ensure exceptional quality and precision for all your mold manufacturing needs.

What is CNC Mold Processing?

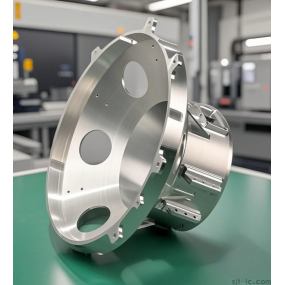

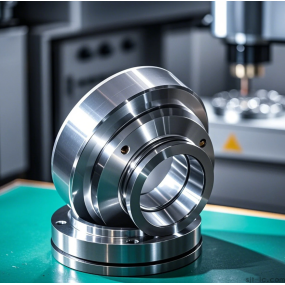

CNC mold processing refers to the manufacturing of molds using computer numerical control (CNC) machines. This advanced technology allows for the creation of highly precise and complex mold components with tight tolerances. At EMAR, we utilize state-of-the-art CNC machining centers to produce injection molds, die-casting molds, stamping dies, and other specialized tooling.

Our CNC Mold Manufacturing Capabilities

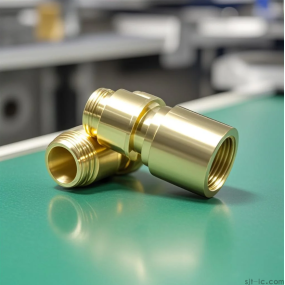

Our facility is equipped with multi-axis CNC machines capable of handling various materials including:

- Tool steels (P20, H13, S7)

- Aluminum alloys (6061, 7075)

- Stainless steels

- Copper alloys

We offer complete CNC mold processing services from design to final production, including:

- 3D CAD/CAM mold design

- High-speed CNC milling

- EDM (Electrical Discharge Machining)

- Precision grinding

- Surface treatment

Why Choose EMAR as Your CNC Mold Manufacturer?

1. Precision Engineering: Our CNC mold processing achieves tolerances as tight as ±.005mm, ensuring perfect mold performance.

2. Advanced Technology: We invest in the latest CNC machining centers with 5-axis capabilities for complex geometries.

3. Quality Assurance: Every mold undergoes rigorous inspection using CMM and other precision measuring instruments.

4. Industry Expertise: With years of experience, we understand the specific requirements for automotive, medical, electronics, and consumer goods molds.

5. Competitive Pricing: Our efficient processes and economies of scale allow us to offer high-quality molds at competitive prices.

Applications of Our CNC Processed Molds

Our CNC manufactured molds serve various industries including:

- Plastic injection molding for consumer products

- Automotive components production

- Medical device manufacturing

- Electronics housing and components

- Aerospace parts

Our CNC Mold Processing Workflow

1. Consultation: Understanding your specific requirements and application needs

2. Design: Creating optimized mold designs using CAD software

3. Material Selection: Choosing the appropriate mold steel or alloy

4. CNC Machining: Precision machining of mold components

5. Finishing: Surface treatment and polishing

6. Testing: Mold trial and quality verification

7. Delivery: On-time shipment with proper documentation

As a trusted CNC mold processing manufacturer, EMAR Company is committed to delivering superior mold solutions that meet your exact specifications. Contact us today to discuss your project requirements and discover how our CNC machining expertise can benefit your production needs.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque