In the realm of precision manufacturing, CNC Machining copper plates stands out as a critical process for industries demanding high conductivity, durability, and intricate designs. At EMAR, we specialize in delivering top-tier CNC solutions tailored to your copper plate requirements, ensuring unmatched accuracy and performance.

Why Choose CNC Machining for Copper Plates?

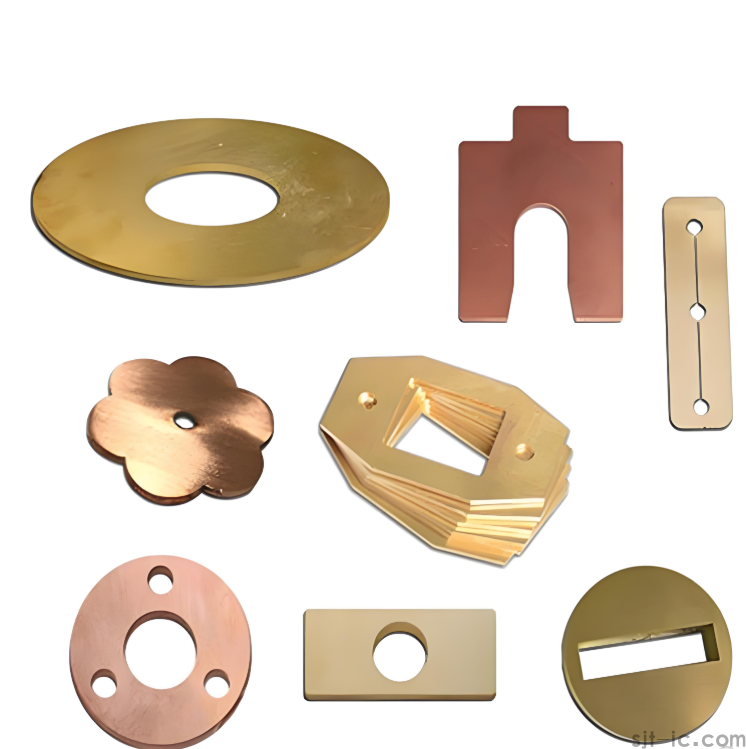

Copper's exceptional thermal and electrical conductivity makes it indispensable for electronics, aerospace, and energy sectors. CNC machining leverages advanced tooling and software to achieve tight tolerances (±.01mm) and complex geometries, overcoming copper's softness and malleability challenges. Our process ensures burr-free edges, smooth finishes, and minimal material waste.

EMAR's CNC Copper Plate Machining Capabilities

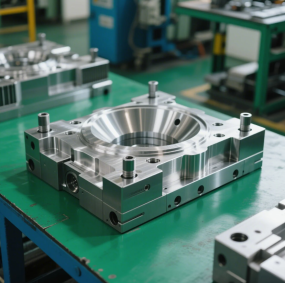

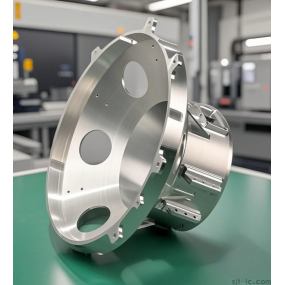

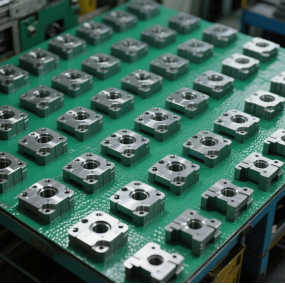

Our facility is equipped with 5-axis CNC mills and lathes, capable of handling copper plates up to 1,200mm × 600mm × 50mm. Key features include:

- Material Expertise: C10100 (OFC), C11000 (ETP), and alloyed copper.

- Surface Treatments: Anti-oxidation plating, polishing, or laser etching.

- Quality Assurance: ISO 9001-certified inspections with CMM measurement reports.

Applications Across Industries

From copper busbars for power distribution to RF shielding components, our machined copper plates serve:

1. Electronics: PCB heat sinks and connectors.

2. Automotive: EV battery terminals.

3. Renewable Energy: Solar panel conductive layers.

Partner with EMAR for fast turnaround (7-15 days), prototype-to-mass-production support, and 24/7 engineering consultations. Visit our website to request a free quote today!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque