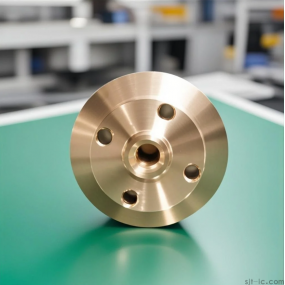

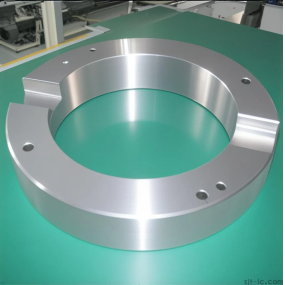

As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision sensor components for industrial applications. This article explores the technical process, material selection, and quality control behind our sensor part production.

Understanding CNC Machined Sensor Components

Sensor components require micron-level precision to ensure accurate signal transmission and environmental resistance. Our 5-axis CNC machining centers achieve tolerances as tight as ±.005mm, critical for pressure sensors, optical encoders, and IoT device parts.

Material Selection for Sensor Applications

We machine sensor housings and components from:

Aerospace-grade aluminum (6061-T6)

Stainless steel (304/316L)

Engineering plastics (PEEK, Ultem)

Copper alloys for conductive parts

EMAR's Quality Assurance Process

Every sensor component undergoes:

In-process CMM inspection

Surface roughness testing (Ra ≤ .8μm)

Functional testing with calibrated equipment

100% final dimensional verification

With ISO 9001-certified manufacturing at our EMAR facility, we deliver mission-critical sensor parts with guaranteed performance specifications and traceable material certifications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque