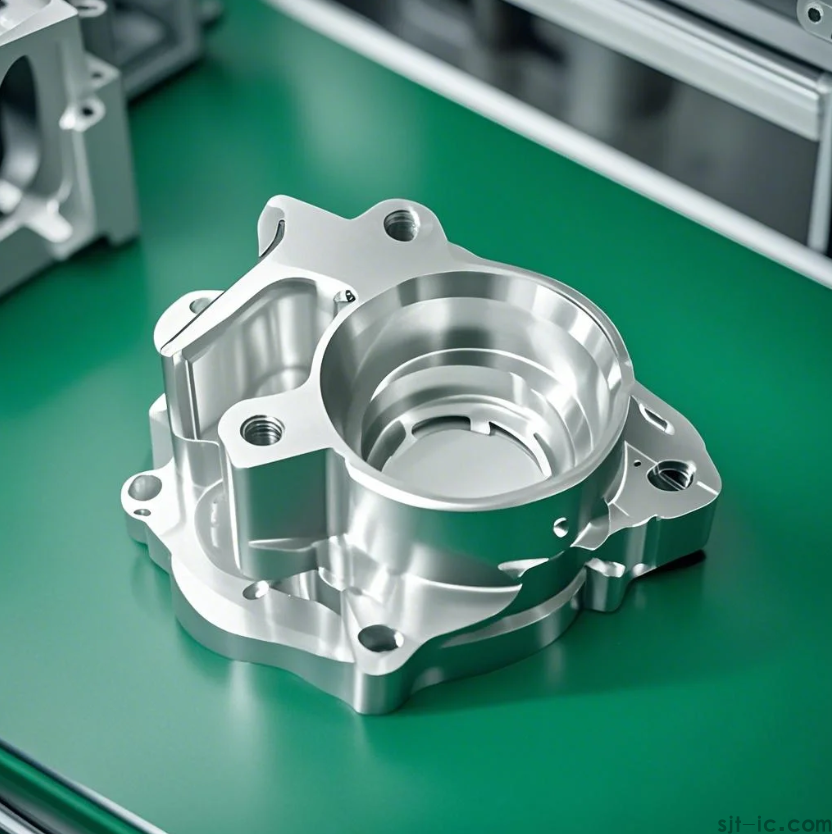

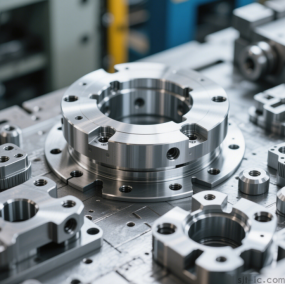

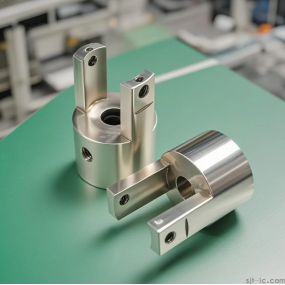

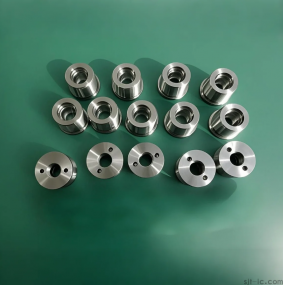

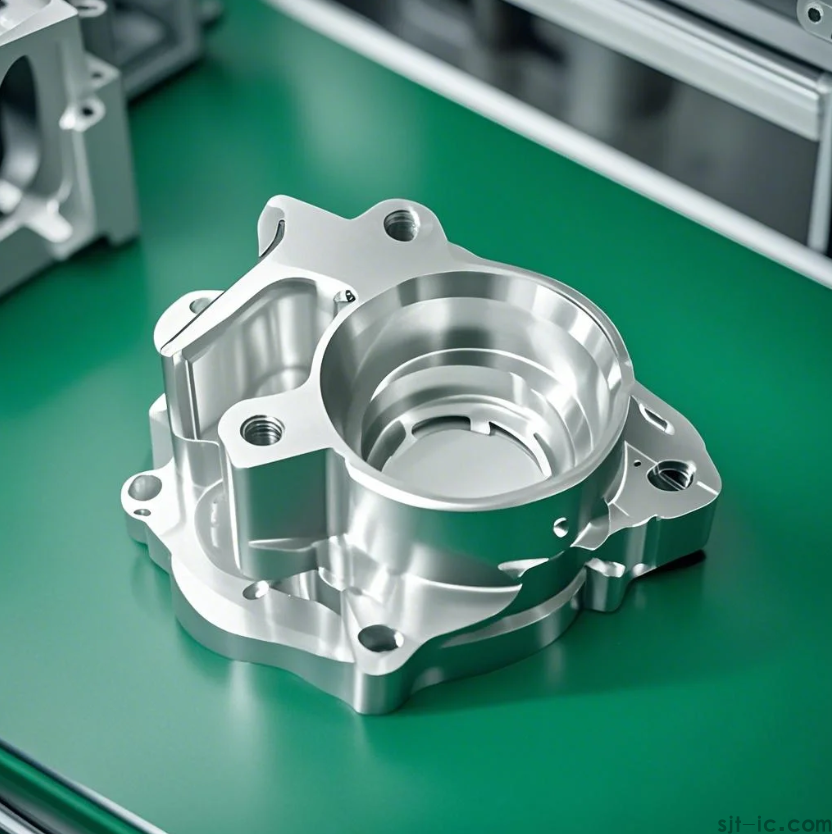

As a leading CNC Machining service provider, EMAR specializes in manufacturing precision complex components for industries ranging from aerospace to medical devices. This article explores the technical capabilities and quality assurance behind our CNC machining solutions.

Technical Challenges in Complex Component Machining

Manufacturing intricate geometries requires advanced 5-axis CNC systems with micron-level accuracy. Our facility employs Swiss-type lathes and multi-pallet machining centers capable of holding ±.005mm tolerances on hardened materials like titanium and Inconel.

Material Expertise

We process over 50 engineering materials including:

Aerospace alloys (7075-T6 aluminum, Ti-6Al-4V)

Medical-grade stainless steels (316L, 17-4PH)

High-temperature plastics (PEEK, Ultem)

Quality Assurance Protocol

Every component undergoes:

In-process CMM verification

Surface roughness testing (Ra .4μm achievable)

100% final inspection per ISO 9001:2015

EMAR's Competitive Advantages

Our 15,000㎡ facility features:

32 CNC machining centers with automated tool changers

Dedicated engineering support for DFM optimization

Flexible MOQ from prototypes to mass production

Contact our technical team at www.sjt-ic.com for component drawings review and instant quoting.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque