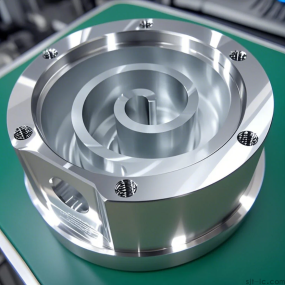

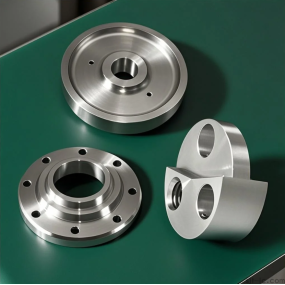

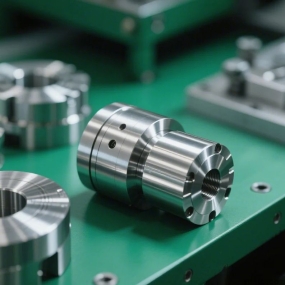

As a professional CNC small batch stainless steel machining service provider, EMAR Technologies specializes in delivering precision components with tight tolerances for industries ranging from aerospace to medical devices. This article will explore the technical nuances of machining stainless steel in small batches while highlighting our competitive advantages.

Why Choose CNC for Small Batch Stainless Steel Parts?

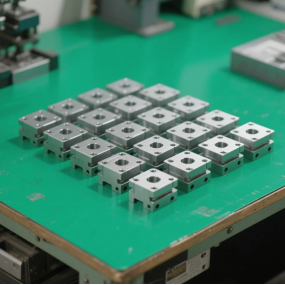

Stainless steel's work-hardening characteristics demand advanced CNC Machining expertise. Our 5-axis CNC centers equipped with coolant-through spindles maintain optimal cutting temperatures, preventing material deformation during small batch production (1-500 pieces). The process offers:

- ±.005mm repeatability across batches

- Surface finishes down to Ra .4μm

- Material flexibility (304, 316, 17-4PH, etc.)

Key Process Considerations

Our technicians implement specialized toolpaths and cutting parameters to address stainless steel's unique challenges:

- Tool Selection: Premium carbide end mills with TiAlN coatings

- Cutting Strategy: Trochoidal milling for heat dissipation

- Quality Control: In-process CMM verification

EMAR's Technical Advantages

With 15+ years in precision CNC machining, we've optimized our small batch workflow:

| Capability | Specification |

|---|

| Maximum Part Size | 600×400×300mm |

| Tolerance Standard | ISO 2768-mK |

| Lead Time | 5-7 days for prototypes |

Contact our engineering team at www.sjt-ic.com for DFM analysis and instant quoting on your small batch stainless steel project.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque