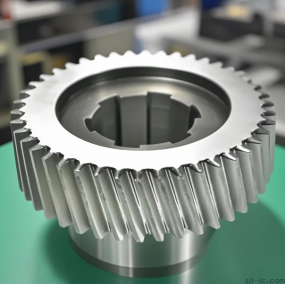

As a leading CNC gear machining provider, EMAR specializes in delivering high-precision, custom-engineered gear solutions for industries ranging from automotive to aerospace. Our advanced CNC technology ensures unmatched accuracy and repeatability for even the most complex gear profiles.

Why Choose Custom CNC Gear Machining?

Custom CNC gear machining offers significant advantages over standard gear production methods. Our process begins with comprehensive CAD/CAM programming to create perfect tooth profiles, followed by multi-axis machining that achieves tolerances within ±.005mm. This level of precision results in gears with superior meshing performance, reduced noise, and extended service life.

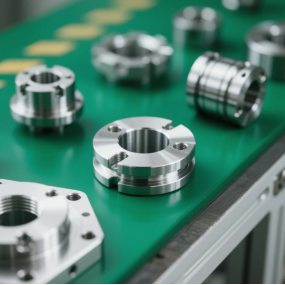

Our CNC Gear Manufacturing Capabilities

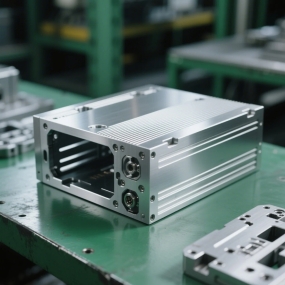

EMAR's facility features state-of-the-art 5-axis CNC machines capable of producing:

Spur gears (module .5-10)

Helical gears (up to 45° helix angle)

Bevel gears (straight and spiral)

Worm gears and worm wheels

Custom splines and sprockets

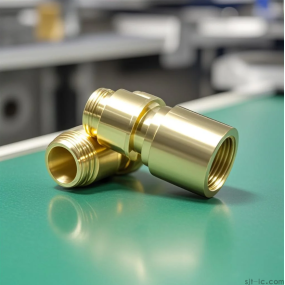

Material Selection for Optimal Performance

We machine gears from various materials including CNC-grade aluminum alloys, stainless steels, tool steels, brass, and engineering plastics. Our material experts help select the optimal combination of strength, wear resistance, and cost-efficiency for your specific application.

Quality Assurance Process

Every custom gear undergoes rigorous inspection using coordinate measuring machines (CMM) and specialized gear testing equipment. We provide complete inspection reports including:

Tooth profile deviation analysis

Runout measurements

Surface finish verification

Hardness testing

With EMAR's CNC gear machining customization services, you receive not just precision components, but complete transmission solutions backed by our engineering expertise. Contact us today to discuss your gear requirements at www.sjt-ic.com.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque