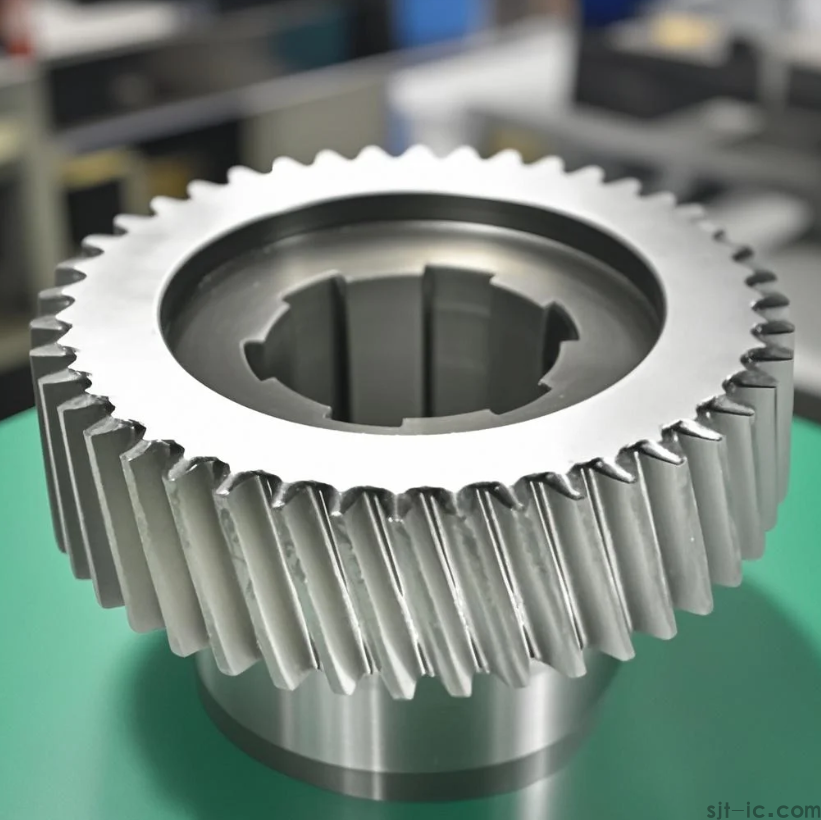

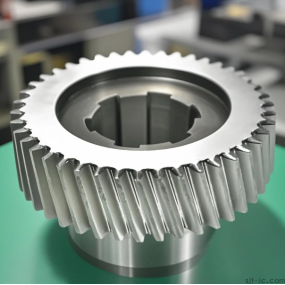

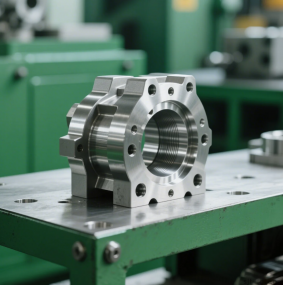

In the realm of modern manufacturing, CNC Machining of non-standard parts plays a pivotal role in delivering customized solutions for industries ranging from aerospace to medical devices. At EMAR, we specialize in transforming complex designs into high-precision components through advanced CNC technology.

What is Non-Standard CNC Machining?

Non-standard CNC machining refers to the production of parts that deviate from conventional dimensions, geometries, or material specifications. These components often require:

Unique toolpath programming

Specialized fixturing solutions

Exotic material handling capabilities

Ultra-tight tolerance control (±.005mm achievable)

EMAR's Technical Advantages in Non-Standard CNC Work

Our CNC machining facility stands out with:

5-axis simultaneous machining centers for complex contours

In-house CAD/CAM engineering support

Material versatility (aluminum, titanium, plastics, etc.)

Surface finishing options from anodizing to mirror polishing

Quality Assurance Process

Every non-standard part undergoes rigorous inspection:

First-article inspection with CMM verification

In-process dimensional checks

Final quality certification (ISO 9001 compliant)

Discover how EMAR's CNC machining expertise can solve your custom manufacturing challenges. Contact our engineering team for project consultation today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque