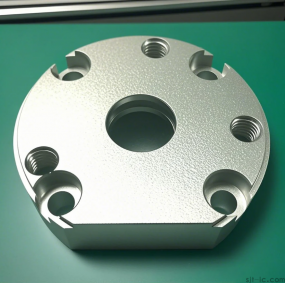

Machine vision inspection equipment is mainly used for the appearance, scale, and shortcomings of precision Metal Stamping products, electronic components, ceramic parts, rubber silicone, screws and nuts, mobile phone parts, automotive fasteners, aviation fasteners, and other products.

If the method of manual inspection is used to detect the appearance and scale quality of the product, the eyes are very easy to cause fatigue, resulting in low power and increased product unqualified rate. If the appearance inspection equipment is used for inspection at this time, the detection accuracy is high, because the machine will not be affected by subjective factors such as happiness, sadness, emotions and desires like people, so it can not only reduce the cost of labor, but also improve the power.  Advantages of machine vision inspection equipment in the inspection of metal stamping parts:

Advantages of machine vision inspection equipment in the inspection of metal stamping parts:

1. It can detect the distance between any circles.

2. It can detect the spacing between the edges of any part.

3. It can detect the center distance, telecentric distance, and near-center distance from any edge to the center of the circle.

4. Check whether the metal stamping products are tilted, missing or poorly sized.

5. Simultaneous detection is performed, and the results can be output through COM, I/O, Internet, and other methods.

6. Capable of storing and querying detection images.

7. Automatic calculation (good products, defective products, total number, etc.).

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque