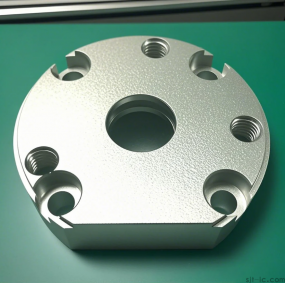

In the production of metal precision stamping, because stamping parts are mass-produced, a lot of waste is generated, and the processing of these Metal Stamping waste is a particularly dangerous task. It is best to use automated equipment for processing, although there are also many wastes that have to be handled manually.

First, let‘s introduce in detail the safety measures for automated processing of hardware waste:

1. When a general sheet material is selected for precision stamping processing, the waste of the metal stamping parts is transported by the conveyor belt, cut short by the scrap shredder, and then restricted into squares by the press;  2. The waste is wound by the receiving drum. In fact, the appearance of the receiving drum is similar to that of the strip steel drum. After the waste of the metal stamping parts is wound by the receiving drum, it can be used as a material for other parts. Because the receiving drum motor is independently driven, it can also be driven by a press or feeding mechanism.

2. The waste is wound by the receiving drum. In fact, the appearance of the receiving drum is similar to that of the strip steel drum. After the waste of the metal stamping parts is wound by the receiving drum, it can be used as a material for other parts. Because the receiving drum motor is independently driven, it can also be driven by a press or feeding mechanism.

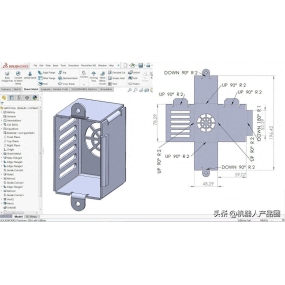

3. Set a cutter on the metal precision stamping die to cut off the waste, and then transfer it to the baler by conveyor belt to press the block. Be careful to cut it at a distance when the press is being carried out.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque