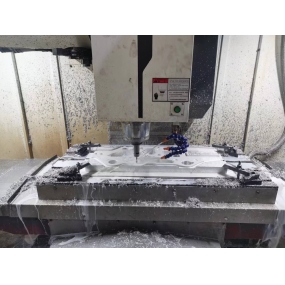

For efficient CNC lathe machining of metal cutting, the material being machined, cutting tools, and cutting conditions are the three major elements. Haec tempus processionis, vita instrumentorum et qualitatem processionis determinant. Metodo processionis economically effectus rationale opus concidi conditionibus esse oportet.

Tres elementi conditionibus CNC lathe machinae secant velocitatem, fertilitatem et profunditatem, quae directo causa ruinam instrumenti. Cum crescere velocitatis, temperatura extinguentis crescet, resultat in mechanica, chemical et thermal vestimenta. Increasing cutting speed by 20% reduces tool life by half.

Relatio inter conditiones pascuae et instrumentum germinatur in minimo intervalo. But with a large feed rate, the cutting temperature rises, and there is significant wear later on. Minus effectus est super instrumentum succidentium quam velocitatem succidentium. Quando effectus profunditates secendi in instrumentis secendi non est tam significatior quam velocitatem et fertilitatem, in micro profunditate secendi, materiae concidit difficile layer producit, quod etiam vitae instrumenti influent.

Users need to choose the cutting speed based on the material being processed, hardness, cutting state, material type, feed rate, cutting depth, etc.

Seleccio optimis conditionium processionis super haec factores est. Regular et stabile vestimenta et lacrima vitae perficiendi est condicio ideale.

However, in practical operations, the choice of tool life is related to tool wear, changes in machined dimensions, surface quality, cutting noise, machining heat, and other factors. When determining the processing conditions, it is necessary to conduct research based on the actual situation. Difficile machinae materiae, sicut stainless steel et calore resistentes alloys, coolantes aut blades cum bona rigiditate utilisar potest.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque