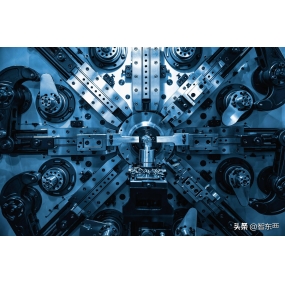

Improvens effectivitatem et qualitatem machinae titanium alloy CNC require comprehensive consideration from multiple aspects. Optimizatio ex sequentibus aspectis exercere potest: 1. Optimizatio parametros machinarum: Machinae distributionis titanium requirit seleccionem adequatum velocitatis sectionis, fertilibus, et profunditates sectionis. Parametros istos, fortitudo et resistentia frictionis reducere potest, et machinum efficabilitatem et qualitatem meliora potest. Meanwhile, reasonable selection of coolant and cutting fluid can also reduce tool wear and improve machining accuracy.  2. Selecting appropriate tool materials and coatings: Based on the processing characteristics of titanium alloys, selecting appropriate tool materials and coatings can improve tool life and processing efficiency. For example, hard alloy cutting tools, diamond cutting tools, etc. are all suitable tools for titanium alloy processing. At the same time, the use of coating technology can improve the hardness and wear resistance of the tool surface, further extending the service life of the tool. 3. Utrum flexibilis principis et subroutinis: In processione mold complex, combination of main program and subroutine can be used to reduce the workload of repetitive programming and improve programming efficiency. Clamante subprogrammam in principio programa simplicere potest, error rate reddere potest, et processere efficabilitatem meliora potest. 4. Reduce the cumulative error of the CNC system: During the programming process, absolute programming should be used as much as possible, so that each program segment is based on the workpiece origin, thereby reducing the cumulative error of the CNC system and ensuring machining accuracy. At the same time, multiple positioning and staged processing can be used during the machining process to reduce machining errors and improve machining accuracy. 5. Efectionis therapis caloris et terra superficie: post processionem titanium alloy, fertilitatem et superficiem tractatum opus est ut difficilior et resistentiam operis ferret. Through reasonable heat treatment and surface treatment processes, the mechanical properties and corrosion resistance of titanium alloy works can be further enhanced, thereby improving their service life.

2. Selecting appropriate tool materials and coatings: Based on the processing characteristics of titanium alloys, selecting appropriate tool materials and coatings can improve tool life and processing efficiency. For example, hard alloy cutting tools, diamond cutting tools, etc. are all suitable tools for titanium alloy processing. At the same time, the use of coating technology can improve the hardness and wear resistance of the tool surface, further extending the service life of the tool. 3. Utrum flexibilis principis et subroutinis: In processione mold complex, combination of main program and subroutine can be used to reduce the workload of repetitive programming and improve programming efficiency. Clamante subprogrammam in principio programa simplicere potest, error rate reddere potest, et processere efficabilitatem meliora potest. 4. Reduce the cumulative error of the CNC system: During the programming process, absolute programming should be used as much as possible, so that each program segment is based on the workpiece origin, thereby reducing the cumulative error of the CNC system and ensuring machining accuracy. At the same time, multiple positioning and staged processing can be used during the machining process to reduce machining errors and improve machining accuracy. 5. Efectionis therapis caloris et terra superficie: post processionem titanium alloy, fertilitatem et superficiem tractatum opus est ut difficilior et resistentiam operis ferret. Through reasonable heat treatment and surface treatment processes, the mechanical properties and corrosion resistance of titanium alloy works can be further enhanced, thereby improving their service life.

Salve! Welcome to the EMAR company website!

Latin

Latin » »

» »

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque