The common quality problems in precision Sheet Metal Processing mainly include material deformation, poor surface quality, dimensional deviation, and poor assembly. Below, we will provide a detailed introduction to these common problems and their corresponding solutions.

1. Material deformation

Materiales are prone to deformation during processing, mainly manifested as twisting, bending, and other problems. The reasons for material deformation may be improper setting of processing parameters, unreasonable mechanical properties of materials, etc.

resolvent:

(1) Reasonable material selection: Choose suitable materials according to actual requirements, with good strength and difficulty.

(2) Reasonably arrange process parameters: Based on the characteristics of materials and processing requirements, set reasonable process parameters to minimize deformation as much as possible.

(3) Using appropriate fixtures: Designing and selecting appropriate fixtures can ensure good positioning of materials during processing and avoid deformation.

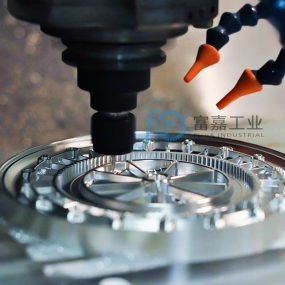

2. Poor surface quality

Qualitate superficie est criterio gravis iudicii qualitatem produktorum manifestata est quasi scratchi, dentes, oxidatio et alios problemos. Reages for poor surface quality may be improper material selection, tool wear, unreasonable processing technology, etc.

resolvent:

(1) Elegite appropriate materials: The materials should have good wear resistance and surface smoothness, which can ensure good surface quality of the processed products.

(2) Reasonable selection of cutting tools: The material and structure of the cutting tools should be chosen reasonably, and the wear of the tools should be checked and replaced in a timely manner to ensure the surface quality of the processed products.

(3) Reasonably optimize processing technology: Based on the actual situation, select processing technology parameters such as feed rate, cutting depth, etc. to improve surface quality.

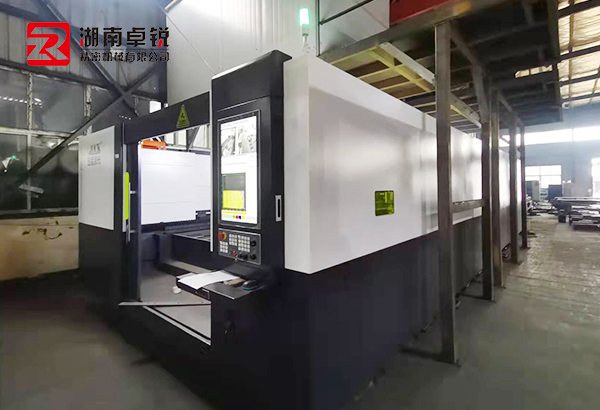

Dimensional deviation

In processione metalla precision sheets, deviation dimensional is a common quality problem, mainly manifestata as the size not meeting the design requirements. Reages for size deviation may be unreasonable processing technology, equipment errors, inaccurate measurements etc.

resolvent:

(1) Reasonable control of processing technology: Based on actual requirements, set processing technology parameters reasonably, minimize processing errors as much as possible, and improve processing accuracy.

(2) Ensure equipment precision: The accuracy of the equipment has a significant impact on the control of machining dimensions, and regular maintenance and calibration of the equipment should be carried out to ensure stable accuracy.

(3) Use appropriate measuring tools: Select appropriate measuring tools for size measurement to ensure measurement accuracy.

4. Poor assembly

Precision sheet metal processing products may require assembly, and poor assembly can directly affect the quality and functionality of the product. Grupus pauperum ecclesiae potest esse minima machina precisa, impropera procedura controla, et non interficientes operatores ecclesiae.

resolvent:

(1) Improvere accuracionem machinarum: confortare potestatem accuracii machinarum, assecura consistentiam partium dimensionum, et evita defectum congregationis causam errorum machinarum.

(2) Optimize process control: Strengthen control over assembly processes, set assembly parameters reasonably, and improve assembly efficiency and quality.

(3) Strengthen worker training: provide technical training and guidance to assembly workers to improve their operational skills and assembly quality.

In summary, common quality issues in precision sheet metal processing include material deformation, poor surface quality, dimensional deviations, and poor assembly. To address these issues, we can improve the quality of precision sheet metal processing products by selecting materials reasonably, optimizing process parameters, using appropriate fixtures and tools, strengthening equipment maintenance and calibration, using appropriate measuring tools, enhancing process control, and worker training.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque