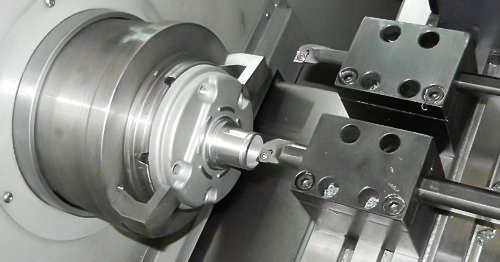

Turning is mainly carried out on lathes, using cutting tools to cut rotating works pieces. On the lathe, corresponding machines can also be carried out using drill bits, reating drills, reamers, taps, die and rolling tools. The machining principle of turning is: the workpiece rotates (main motion), and the turning tool moves in a straight or curved line in a plane (feed motion), which can be used to machine inner and outer cylindrical surfaces, end faces, conical surfaces, forming surfaces, and threads. Cum circumferens superficies cylindricas, instrumentum conversationis in direction parallel ad axim rotationis opus movetur. Cum facies finis aut partes operantibus convertere, i instrumentum conversationis horizontale movet in direction perpendiculare ad axim rotationis operantis. Si direction of motion of the turning tool is in an oblique angle to the axis of rotation of the workpiece, it can be machined in a conical surface.

Precisiones ad convertendum operationem:

Precisiones ad convertendum operationem:

(1) Prius initio opus, lubricate lathe et verificate si manus est in loco. Exercite lathe lentem 5 minutis ut confirmare omnia normal antequam operatur.

(2) Punctus pulcherrimus induri oportet, et pulcherrimus non relinquetur super eam;

(3) Laboratorium et instrumentum securi clampendum est, et instrumentum tenentem non multo longum extendetur (exceptis ferentibus holarum). Cum parvulum instrumentum tenentem rotaturum est, cessare potest instrumentum collidi cum fractum, fabricationem, aut manum secere.

(4) Cum currit funiculus, non stabat populus in conspectu eius, nec inponat super latum, nec inponat super latum olei pedibus suis.

(5) Pro securitatem securitatem in alta velocitate cutatione, instrumentum cutationis et schermum gearis utilizatur;

(6) Prohibit velocitatem fremationem reversam, et custodi exitum et parkamentum rectum;

(7) Transferentes ferreae filios, folium aut maculam specialem utilizatur;

(8) Ut fichium utilizat ad pulserem opus, dextera antequam et sinistra post tergum est; Ut gaudium ut pulseretur opus, instrumenta, sicut palmas manus, ut non adprehenderet vulnera.

(9) Omnia instrumenta reusata, instrumenta mensura, et instrumenta succidentia in proximo loco securo posita sunt et custoditur pura et ordine;

(10) Transferentes aut mensentes opera ante faciem transportationis expectate ut veniat ad perfectam firmam antequam operaretur

(11) When the lathe is working, it is forbidden to open or remove the protective device;

(12) Quo adpropinquat opus, lathe mundabitur et extinguetur, et caudam et canistrum ad finem dextram latus revertetur.

The main parameters of turning machining are the back cutting amount and feed rate. The back cutting amount refers to the maximum size of the cutting layer perpendicular to the feed rate direction, generally referring to the vertical distance between the machined surface and the surface to be machined on the workpiece. Feed rate refert to the relative displacement of the workpiece (or tool) in the direction of the feed motion for each rotation or reciprocating motion of the workpiece (or tool), or for each tooth rotated by the tool. During rough machining, try to use a larger back cutting and feed rate to improve productivity, while during fine machining, i choose a smaller back cutting and feed rate to ensure the required machining accuracy and surface quality of the workpiece.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque