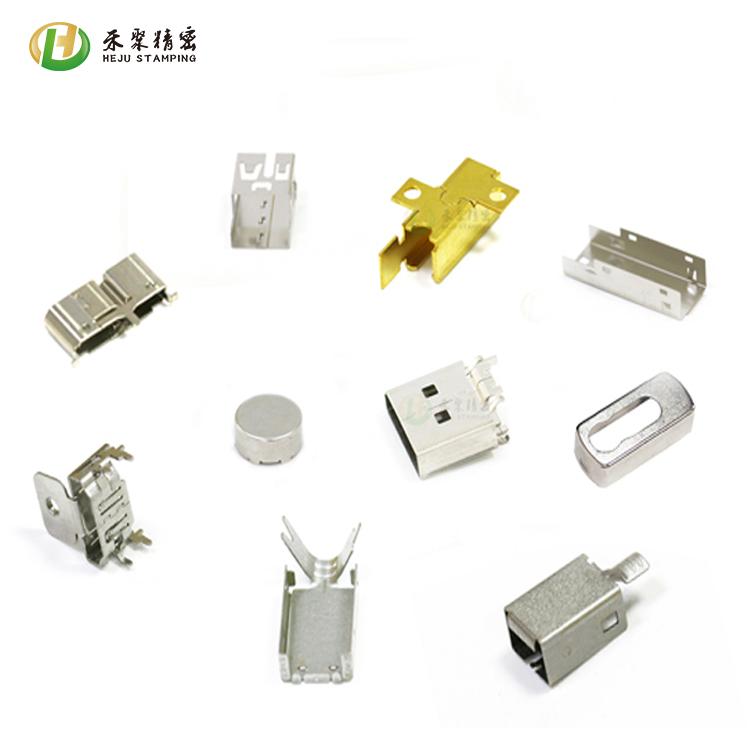

Sheet metal is one of the three elements of stamping processing. The performance requirements for electronic hardware stamping parts and electronic stamping parts involve physical properties such as material hardness, tensile strength, and shear strength. Stamping forming process involves stamping cutting, stamping bending, stamping stretching and other related processes. Inter multitudinem materiae metallorum, unusquisque materiae propriae propria habet, et designatores generalmente iudicant si hoc processum adequatum est huic materiae in proprietatibus suis.

When cold rolling carbon steel sheets and strips for electronic hardware stamping parts and electronic stamping materials, they are suitable for products with lower stamping processing degree, such as punching, bending, etc. Stella est adequa ad stampionem et extensionem, et ad stampionem partes cum repetitione stampionis aut superformatum SPCE: effectus tensilis maior est quam SPCD, et superficie electroplate debet (hic materia minus frequenter utilitur).

Materium SECC cum galvanizato layer equipped, which has good anti-corrosion performance. Generally used for stamping appearance parts of electronic hardware stamping parts.

Stella stabilis habet proprietates fisicas, sicut alta fortitudo, alta fortitudo, resistentia corrosionis, perfectionem bonum et proprietates antibacteriorum. Select the appropriate material grade according to the functional requirements of the stamped parts during stamping processing.

Stainless steel 301: It has a relatively low chromium content and poor corrosion resistance, but the material can achieve high tensile strength and hardness after heat treatment, and has good elastic properties. It exhibits obvious work hardening phenomenon during deformation and is used in various situations that require high strength.

Stella Stainless 304: Content carbon, strength, and hardness are all lower than SUS301. But the material added has strong corrosion resistance. Alta fortitudo et fortitudo per calore trationem possunt attingere. Widely used in the production of equipment and components that require good comprehensive performance (corrosion resistance and formability).

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque