Why Partner with a Specialized Aluminum CNC Machining Manufacturer?

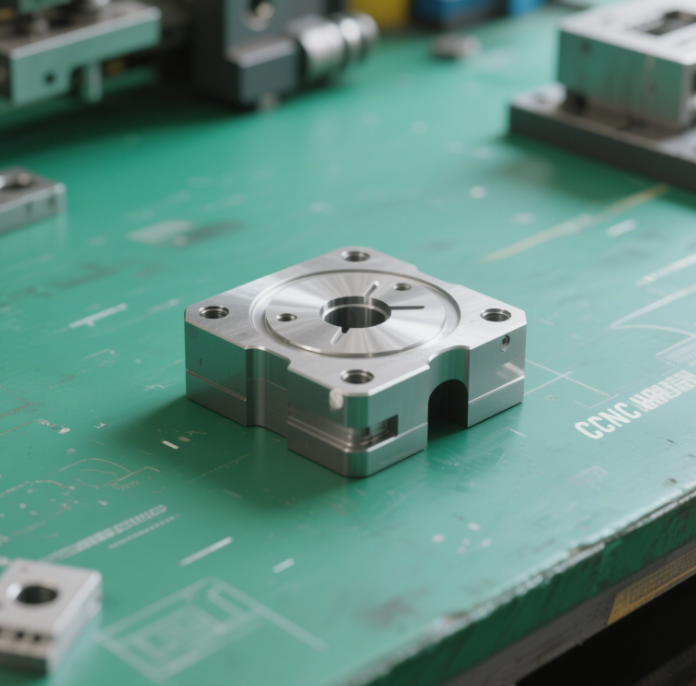

When sourcing precision components, partnering with an experienced aluminum CNC machining manufacturer like EMAR ensures superior quality, tight tolerances (±.01mm), and cost-effective production. Our ISO-certified facility combines advanced 5-axis CNC systems with aerospace-grade material expertise to deliver complex geometries for automotive, robotics, and medical industries.

EMAR’s Technical Capabilities in Aluminum Machining

With 15+ years in CNC manufacturing, EMAR offers:

- High-speed machining (up to 20,000 RPM) for mirror finishes

- Anodizing, powder coating, and chemical conversion surface treatments

- Prototype-to-mass production with 98% on-time delivery rate

How Our Process Solves Industry Pain Points

Common challenges like material warping or tool wear are mitigated through:

1. Pre-machining stress relief protocols

2. Custom coolant strategies for 6061/7075 alloys

3. In-process CMM verification for critical dimensions

Request Your Custom Quote Today

Visit EMAR's official website to upload your CAD files for a DFM analysis and competitive pricing within 24 hours. Our engineering team provides design-for-manufacturability consultations at no cost.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque