Understanding Flange Plate CNC Machining

Flange plate CNC machining is a precision manufacturing process that utilizes computer numerical control (CNC) technology to create high-quality flange components. As a critical connection element in piping systems, flanges require exceptional dimensional accuracy and surface finish, which CNC machining can consistently deliver.

Key Steps in the Flange CNC Machining Process

Our CNC machining process for flange plates follows these essential steps:

Material Selection: Choosing appropriate metal alloys (stainless steel, carbon steel, aluminum, etc.)

CNC Programming: Creating precise tool paths using CAD/CAM software

Facing Operation: Achieving perfect flatness on mounting surfaces

Bore Machining: Creating accurate center holes with tight tolerances

Bolt Hole Drilling: Positioning and drilling mounting holes with CNC precision

Surface Finishing: Applying required surface treatments (anodizing, plating, etc.)

Advantages of Choosing EMAR for Your Flange Machining Needs

EMAR stands out in flange plate CNC machining due to our:

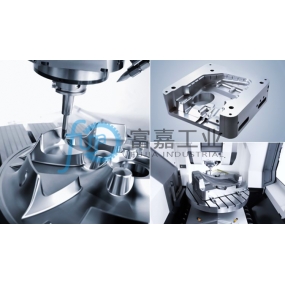

Advanced 5-axis CNC machines capable of complex geometries

±.005mm machining tolerance for critical applications

In-house quality control with CMM inspection

Material traceability and certification

Flexible production from prototypes to mass production

Applications of CNC Machined Flange Plates

Our precision machined flanges serve various industries including:

Oil and gas pipeline systems

Chemical processing equipment

Power generation facilities

Water treatment plants

Industrial machinery

Why CNC Machining is Ideal for Flange Production

Compared to traditional manufacturing methods, CNC machining offers:

Higher dimensional accuracy and consistency

Faster production times for complex designs

Better surface finishes right off the machine

Easier modification of designs through software

Reduced material waste through optimized tool paths

At EMAR, we combine our technical expertise with state-of-the-art CNC equipment to deliver flange plates that meet the most demanding specifications. Contact us today to discuss your specific flange machining requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque