Understanding 5-Axis CNC Machining Quotes

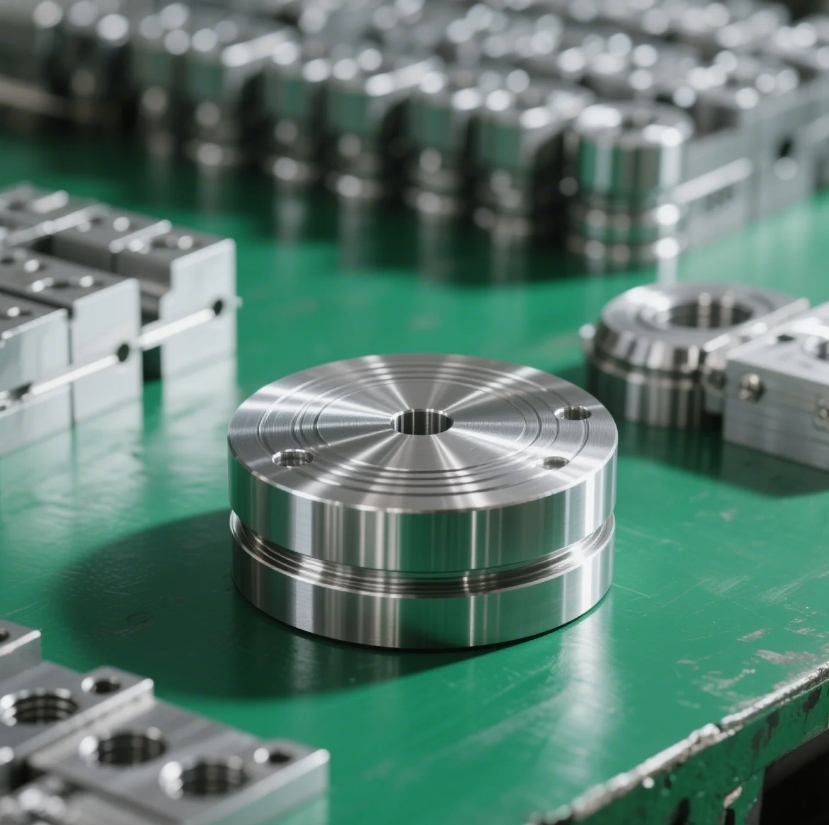

When requesting a 5-axis CNC machining quote, buyers often encounter significant price variations between suppliers. As an industry-leading CNC service provider with 15+ years of experience, EMAR explains the key components that determine machining costs and how our optimized processes deliver competitive pricing without compromising quality.

Key Factors Affecting 5-Axis Machining Costs

1. Part Complexity: 5-axis machines excel at complex geometries, but intricate designs requiring continuous multi-axis movement increase programming time and machining hours.

2. Material Selection: Aerospace aluminum (6061-T6) typically costs $25-$35/kg for machining, while titanium (Grade 5) ranges $80-$120/kg due to slower cutting speeds and tool wear.

3. Tolerance Requirements: Standard ±.1mm tolerances maintain baseline pricing, while ±.025mm or tighter specifications may increase costs by 30-50%.

4. Surface Finish Needs: Standard Ra 3.2μm comes at base price, while mirror finishes (Ra .4μm) require additional polishing steps.

EMAR's Cost Optimization Approach

Our 5-axis CNC machining services implement several strategies to provide competitive quotes:

• Advanced CAM Programming: Our Mastercam-certified programmers create optimized toolpaths that reduce air cutting by up to 40%.

• Tooling Management: Strategic use of specialized tool coatings extends tool life by 300% when machining hardened steels.

• Batch Processing: Combining multiple orders allows shared setup costs, offering 15-25% savings for prototype quantities.

Transparent Quoting Process

EMAR provides detailed breakdowns in our quotes:

1. Material Cost: Calculated based on exact billet size plus 15% machining allowance

2. Machine Time: Estimated using our database of 5,000+ similar parts

3. Secondary Operations: Anodizing, heat treatment quoted separately

4. Quality Control: CMM inspection included standard

For accurate 5-axis CNC machining quotes, submit your CAD files to our engineering team at quotes@sjt-ic.com. Typical response time: 4-8 business hours for standard parts, 24 hours for complex assemblies.

Why EMAR Delivers Better Value

• 12 Haas UMC-750 5-axis machines with 700mm pallets

• ISO 9001:2015 certified quality system

• 98% on-time delivery record in 2024

• Free DFM feedback with every quote

Contact our technical sales team today to discuss your project's specific requirements and receive a competitive quote tailored to your needs.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque