As a leading CNC Machining service provider, EMAR specializes in manufacturing high-precision stainless steel components for medical applications. Our advanced CNC technology ensures exceptional quality and compliance with strict medical industry standards.

Why Choose CNC Machining for Medical Stainless Steel Parts?

Medical applications demand components with superior corrosion resistance, biocompatibility, and dimensional accuracy. Stainless steel medical parts produced through CNC machining offer these critical characteristics while maintaining excellent mechanical properties.

Our CNC Machining Capabilities for Medical Components

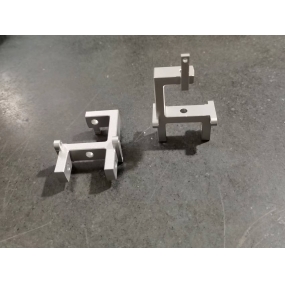

EMAR's state-of-the-art CNC equipment handles various medical-grade stainless steels (304, 316L, 17-4PH) with micron-level precision. We manufacture:

- Surgical instruments

- Implantable components

- Diagnostic equipment parts

- Medical device housings

Quality Assurance for Medical Applications

All our medical CNC machining processes follow ISO 13485 standards. We implement strict quality control measures including:

- Material traceability

- Surface finish validation

- Dimensional verification

- Biocompatibility testing

Advantages of Partnering with EMAR

Our medical clients benefit from:

- FDA-compliant manufacturing

- Cleanroom machining options

- Validated sterilization processes

- Prototype to mass production support

Visit our website to learn more about our CNC machining services for medical applications or request a quote for your next project.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque