In modern manufacturing, precision CNC batch processing has become the cornerstone for producing high-quality, consistent parts across industries. At EMAR, we specialize in delivering exceptional batch machining services that meet the most demanding specifications while maintaining cost-efficiency.

What Is Precision CNC Batch Processing?

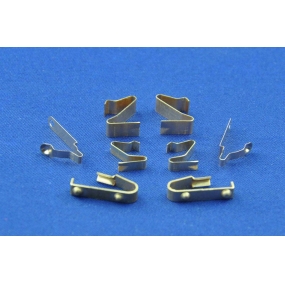

Precision CNC batch processing refers to the manufacturing of multiple identical parts using computer numerical control machines with tight tolerances (typically ±.005mm or better). This method combines the efficiency of mass production with the accuracy of CNC Machining, making it ideal for industries requiring large quantities of precision components.

Key Advantages of Our Batch Processing Services

1. Consistent Quality: Our advanced CNC machines maintain identical specifications across thousands of parts

2. Cost Efficiency: Reduced per-unit costs through optimized production workflows

3. Material Versatility: Capable of processing aluminum, stainless steel, titanium, and engineering plastics

4. Quick Turnaround: Automated processes enable faster production cycles

EMAR's Technical Capabilities

Our facility features:

- 25+ multi-axis CNC machining centers

- High-speed machining capabilities up to 20,000 RPM

- In-process quality control with CMM inspection

- Dedicated batch processing production lines

Industries We Serve

Our precision batch machining solutions support:

• Automotive components

• Aerospace fittings

• Medical device parts

• Electronics enclosures

• Industrial equipment

Why Choose EMAR for Your Batch Processing Needs?

With 15+ years of CNC machining experience, EMAR offers:

- ISO 9001:2015 certified processes

- DFM (Design for Manufacturing) support

- Flexible order quantities from 100 to 100,000+ units

- Comprehensive post-processing options

- Strict confidentiality agreements

Contact our engineering team at www.sjt-ic.com to discuss your specific batch processing requirements and receive a competitive quote within 24 hours.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque