When sourcing CNC Machining services, reliability becomes the paramount concern for procurement managers and engineers. EMAR Company, with our ISO 9001-certified facility and decade-long expertise, stands as your trusted partner for precision manufacturing solutions.

How to Evaluate a Reliable CNC Machining Provider

Three critical factors determine a provider's reliability:

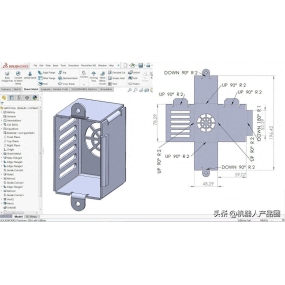

- Technical Capabilities: Our 30+ advanced CNC centers (5-axis to Swiss-type) handle ±.005mm tolerances

- Quality Systems: In-process inspections with CMM and vision measurement systems

- Industry Experience: 12 years serving aerospace, medical, and automotive sectors

EMAR's Reliablity Advantages in CNC Machining

We differentiate through:

- Material traceability systems for aerospace-grade aluminum and titanium

- Dedicated engineering support from DFM analysis to post-processing

- On-time delivery record of 98.7% across 5,000+ annual projects

Why Global Clients Trust Our CNC machining Services

Our clients including Fortune 500 manufacturers consistently choose EMAR for:

- Nadcap-accredited special processes (anodizing, heat treatment)

- Prototype-to-production scalability with identical quality standards

- ITAR-compliant data security for defense projects

For your next CNC machining project, request a free DFM analysis at www.sjt-ic.com or email engineering@emar.com. Our team responds within 2 business hours with technical solutions.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque